Aluminum Gas Cylinder for Fire Extinguishers

- Standard: DOT, TPED, GB/T

- Material: aluminum alloy 6061-T6

- Applications: residential, commercial, and vehicular fire protection systems

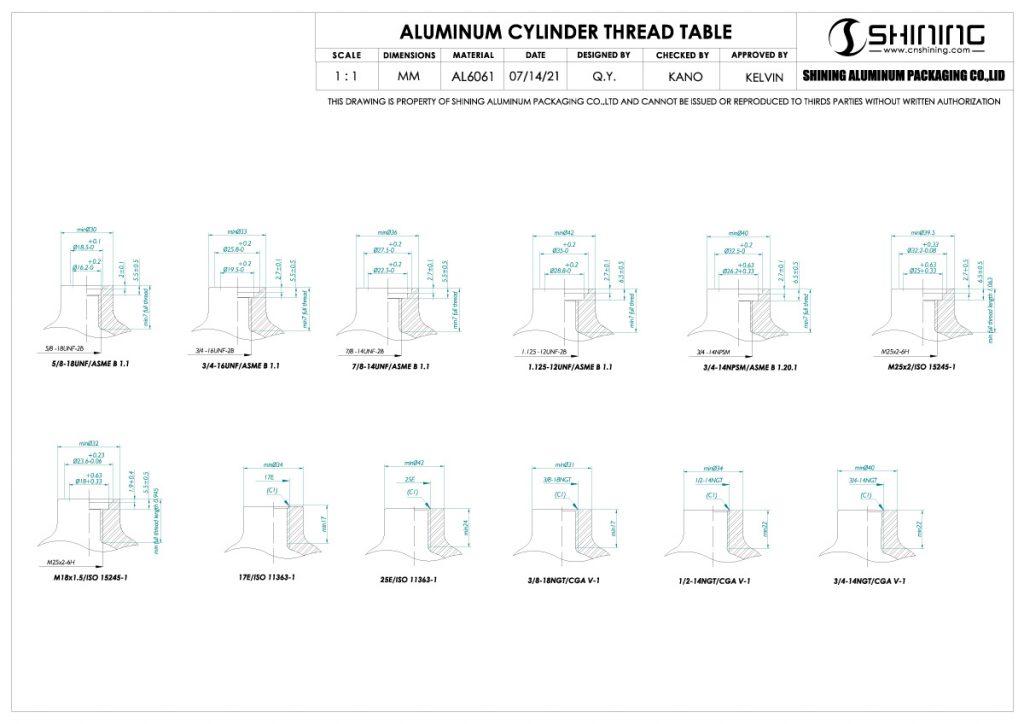

- Valve & Thread: Specified & Installed Upon Request

- Size: Custom Size is available with the TPED/DOT Certified Range

- Finish: Unpainted & Brushed & Different Color Coated

- Delivery time: Usually 30-40 days Upon Quantity

Our lightweight, durable and corrosion-resistant fire protection cylinder are the ideal choice for residential, commercial, and vehicular fire protection systems.

- Material: We utilize a spectrum analyzer to ensure the stability of the material for aluminium gas cylinders, which are composed of aluminium alloy 6061-T6.

- Surface Finish: We offer a range of customization possibilities for the surface finish of aluminium cylinders. These options include polishing, body painting, and more.

- Automatic Production: Utilizing automatic shaping machinery ensures the seamless refinement of cylinder interfaces, consequently elevating their safety quotient.

- Size Customizing: We welcome orders for customized sizes, as long as they fall within our certified range. Kindly furnish us with the specifications to enable us to assess and offer technical illustrations accordingly.

In the realm of fire safety, having a dependable fire extinguisher is paramount. A vital component that ensures the extinguisher’s efficacy is the aluminum gas cylinder. As a renowned supplier, manufacturer, and company in the aluminum gas cylinder industry, we take immense pride in offering top-notch aluminium gas cylinders for fire extinguishers. In this article, we’ll delve into the advantages and applications of these essential cylinders, shedding light on why they are the preferred choice for fire safety professionals.

Supplier, Manufacturer, and Company Expertise

Our company stands tall as a leading supplier, manufacturer, and company specializing in aluminum gas cylinders. With years of experience under our belt, we have mastered the art of producing high-quality aluminum gas cylinders that meet and exceed industry standards. Our commitment to excellence and continuous innovation has earned us a reputation as a trusted partner for fire safety solutions.

Advantages of Aluminum Gas Cylinders

- Lightweight and Durable: Aluminum is renowned for its exceptional strength-to-weight ratio. Our gas cylinders are lightweight yet robust, making them easy to handle during emergencies while ensuring extended durability.

- Corrosion Resistance: One of the standout features of aluminum is its natural corrosion resistance. This inherent property ensures that our cylinders remain reliable even in harsh environmental conditions, prolonging their lifespan.

- Rapid Heat Dissipation: Aluminum’s excellent thermal conductivity allows for swift heat dissipation. In a fire extinguishing scenario, this attribute facilitates rapid cooling of the cylinder, preventing overheating and ensuring optimal performance.

- Eco-Friendly: Aluminum is fully recyclable, aligning with modern sustainability principles. By opting for our aluminum gas cylinders, you’re not only enhancing safety but also contributing to a greener future.

Versatile Applications

Our aluminum gas cylinders find applications across a wide spectrum of fire extinguisher types, including:

- Portable Extinguishers: The lightweight nature of aluminum gas cylinders makes them an ideal choice for portable fire extinguishers, enabling easy manoeuvrability during emergencies.

- Automotive Fire Suppression Systems: Automobiles, buses, and other vehicles rely on aluminum gas cylinders for their fire suppression systems. The cylinders’ compact design and durability ensure reliable fire safety within the confined spaces of vehicles.

- Industrial Fire Protection: Industries require robust fire extinguishers to safeguard their operations. Aluminum gas cylinders, with their corrosion resistance and high-performance characteristics, are a staple in industrial fire protection setups.

- Marine Fire Safety: The maritime sector benefits from aluminum gas cylinders due to their resistance to saltwater corrosion. They play a pivotal role in marine fire safety systems aboard ships and vessels.

In conclusion, our company is your ultimate destination for premium aluminum gas cylinders for fire extinguishers. As a distinguished supplier, manufacturer, and company, we bring together expertise, innovation, and a commitment to safety. With advantages such as lightweight durability, corrosion resistance, rapid heat dissipation, and eco-friendliness, these cylinders cater to diverse applications within the fire safety landscape. Choose our aluminum gas cylinders to bolster your fire safety arsenal and secure a safer environment for all.

Aluminum gas Cylinders Size

DOT 3AL Aluminum Gas Cylinder

| NO. | Outside Diameter | Service Pressure | Test pressure | Water Volume | Certified | Standard | Certification Body | ||||||

| Liters | lbs | ||||||||||||

| mm | in | bar | psi | bar | psi | min | max | min | max | ||||

| 1 | 50 | 1.97 | 250 | 3625 | 417 | 6042 | 0.26 | 0.46 | 0.57 | 1.01 | DOT | DOT 3AL | DOT |

| 2 | 60 | 2.36 | 166 | 2408 | 250 | 3626 | 0.35 | 0.65 | 0.77 | 1.43 | DOT | UN ISO7866 | DOT |

| 3 | 61 | 2.40 | 207 | 3000 | 345 | 5000 | 0.4 | 0.7 | 0.88 | 1.54 | DOT | DOT 3AL | DOT |

| 4 | 73.8 | 2.91 | 160 | 2321 | 200 | 2901 | 0.62 | 0.62 | 1.36 | 1.36 | DOT | DOT 39 | DOT |

| 5 | 73.8 | 2.91 | 120 | 1740 | 180 | 2611 | 0.2 | 1.5 | 0.44 | 3.31 | DOT | UN ISO11118 | DOT |

| 6 | 73.8 | 2.91 | 150 | 2176 | 225 | 3263 | 0.2 | 1.5 | 0.44 | 3.31 | DOT | UN ISO11118 | DOT |

| 7 | 81.5 | 3.21 | 153 | 2216 | 255 | 3694 | 0.6 | 1.3 | 1.32 | 2.87 | DOT | DOT 3AL | DOT |

| 8 | 81.5 | 3.21 | 124 | 1800 | 207 | 3000 | 0.63 | 1.17 | 1.39 | 2.58 | DOT | DOT 3AL | DOT |

| 9 | 90 | 3.54 | 207 | 3000 | 345 | 5000 | 0.92 | 1.68 | 2.03 | 3.70 | DOT | DOT 3AL | DOT |

| 10 | 111.3 | 4.38 | 139 | 2015 | 232 | 3359 | 1.2 | 2 | 2.65 | 4.41 | DOT | DOT 3AL | DOT |

| 11 | 111.3 | 4.38 | 124 | 1800 | 207 | 3000 | 0.98 | 1.82 | 2.16 | 4.01 | DOT | DOT 3AL | DOT |

| 12 | 111.3 | 4.38 | 139 | 2015 | 232 | 3359 | 2.52 | 4.68 | 5.56 | 10.32 | DOT | DOT 3AL | DOT |

| 13 | 133.4 | 5.25 | 153 | 2216 | 255 | 3694 | 3.9 | 7 | 8.60 | 15.43 | DOT | DOT 3AL | DOT |

| 14 | 133.4 | 5.25 | 124 | 1800 | 207 | 3000 | 2.38 | 4.42 | 5.25 | 9.74 | DOT | DOT 3AL | DOT |

TPED EN ISO7866 Aluminum Gas Cylinder

| NO. | Outside Diameter | Service Pressure | Test pressure | Water Volume | Certified | Standard | Certification Body | ||||||

| Liters | lbs | ||||||||||||

| mm | in | bar | psi | bar | psi | min | max | min | max | ||||

| 1 | 60 | 2.36 | 166 | 2408 | 250 | 3626 | 0.4 | 0.67 | 0.88 | 1.48 | TPED | EN ISO7866 | TUV |

| 2 | 60.5 | 2.38 | 200 | 2901 | 300 | 4351 | 0.35 | 0.7 | 0.77 | 1.54 | TPED | EN ISO7866 | TUV |

| 3 | 80 | 3.15 | 32 | 464 | 48 | 696 | 0.6 | 1.5 | 1.32 | 3.31 | TPED | EN ISO7866 | TI |

| 4 | 70 | 2.76 | 120 | 1740 | 180 | 2611 | 0.2 | 1.2 | 0.44 | 2.65 | TPED | EN ISO11118 | TUV |

| 5 | 73.8 | 2.91 | 120 | 1740 | 180 | 2611 | 0.2 | 1.3 | 0.44 | 2.87 | TPED | EN ISO11118 | TUV |

| 6 | 81.5 | 3.21 | 124 | 1798 | 186 | 2698 | 0.6 | 1.5 | 1.32 | 3.31 | TPED | EN ISO7866 | TUV |

| 7 | 90 | 3.54 | 200 | 2901 | 300 | 4351 | 0.7 | 1.6 | 1.54 | 3.53 | TPED | EN ISO7866 | TUV |

| 8 | 90 | 3.54 | 166 | 2408 | 250 | 3626 | 0.7 | 1.6 | 1.54 | 3.53 | TPED | EN ISO7866 | TUV |

| 9 | 111 | 4.37 | 124 | 1798 | 186 | 2698 | 1.4 | 3.9 | 3.09 | 8.60 | TPED | EN ISO7866 | TUV |

| 10 | 111 | 4.37 | 200 | 2901 | 300 | 4351 | 1.4 | 4 | 3.09 | 8.82 | TPED | EN ISO7866 | TUV |

| 11 | 120 | 4.72 | 166 | 2408 | 250 | 3626 | 1.4 | 4.5 | 3.09 | 9.92 | TPED | EN ISO7866 | TUV |

| 12 | 140 | 5.51 | 166 | 2408 | 250 | 3626 | 4 | 8 | 8.82 | 17.64 | TPED | EN ISO7866 | TUV |

| 13 | 140 | 5.51 | 200 | 2901 | 300 | 4351 | 3 | 9 | 6.61 | 19.84 | TPED | EN ISO7866 | TUV |

| 14 | 184 | 7.24 | 166 | 2408 | 250 | 3626 | 6 | 15 | 13.23 | 33.07 | TPED | EN ISO7866 | TUV |

| 15 | 184 | 7.24 | 200 | 2901 | 300 | 4351 | 6 | 16 | 13.23 | 35.27 | TPED | EN ISO7866 | TUV |

| 16 | 203 | 7.99 | 166 | 2408 | 250 | 3626 | 11 | 20 | 24.25 | 44.09 | TPED | EN ISO7866 | TUV |

GB/T 11640 Aluminum Gas Cylinder

| NO. | Outside Diameter | Service Pressure | Test pressure | Water Volume | Certified | Standard | Certification Body | ||||||

| Liters | lbs | ||||||||||||

| mm | in | bar | psi | bar | psi | min | max | min | max | ||||

| 1 | 60 | 2.36 | 150 | 2176 | 225 | 3263 | 0.2 | 0.6 | 0.44 | 1.32 | TS | GB/T 11640 | TS |

| 2 | 60 | 2.36 | 300 | 4351 | 450 | 6527 | 0.2 | 0.5 | 0.44 | 1.10 | TS | GB/T 11640 | TS |

| 3 | 81.5 | 3.21 | 150 | 2176 | 225 | 3263 | 0.7 | 1.5 | 1.54 | 3.31 | TS | GB/T 11640 | TS |

| 4 | 111.3 | 4.38 | 200 | 2901 | 300 | 4351 | 1.1 | 4 | 2.43 | 8.82 | TS | GB/T 11640 | TS |

| 5 | 140 | 5.51 | 150 | 2176 | 225 | 3263 | 3 | 9 | 6.61 | 19.84 | TS | GB/T 11640 | TS |

| 6 | 140 | 5.51 | 200 | 2901 | 300 | 4351 | 3 | 9 | 6.61 | 19.84 | TS | GB/T 11640 | TS |

| 7 | 184 | 7.24 | 200 | 2901 | 300 | 4351 | 6 | 15 | 13.23 | 33.07 | TS | GB/T 11640 | TS |

| 8 | 203 | 7.99 | 150 | 2176 | 225 | 3263 | 8 | 20 | 17.64 | 44.09 | TS | GB/T 11640 | TS |