Aluminum Gas Cylinders for Specialty & Industrial

- Standard: DOT, TPED, GB/T

- Material: aluminium alloy 6061-T6

- Applications: Highly volatile, exotic, and speciality gases for industrial uses

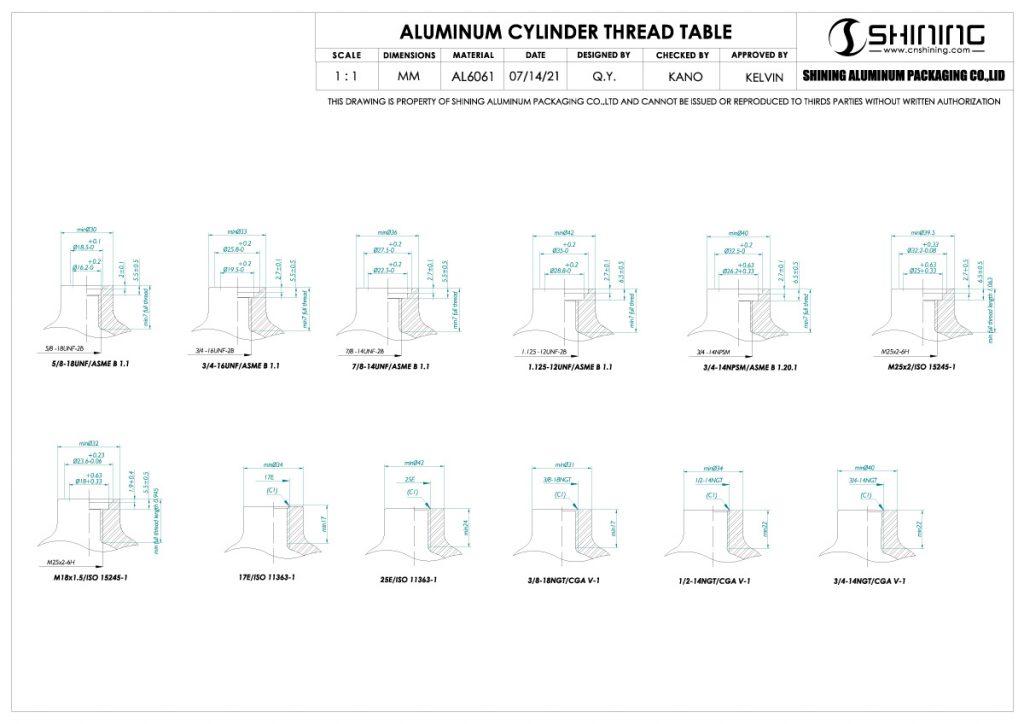

- Valve & Thread: Specified & Installed Upon Request

- Size: Custom Size is available with the TPED/DOT Certified Range

- Finish: Unpainted & Brushed & Different Color Coated

- Delivery time: Usually 30-40 days Upon Quantity

Our gas cylinders are designed for applications in which gas stability and purity are essential for the manufacturing of a range of products and industrial applications, for high-pressure storage of highly volatile, exotic, and speciality gases for industrial uses.

- Material: We utilize a spectrum analyzer to ensure the stability of the material for aluminium gas cylinders, which are composed of aluminium alloy 6061-T6.

- Surface Finish: We offer a range of customization possibilities for the surface finish of aluminium cylinders. These options include polishing, body painting, and more.

- Automatic Production: Utilizing automatic shaping machinery ensures the seamless refinement of cylinder interfaces, consequently elevating their safety quotient.

- Size Customizing: We welcome orders for customized sizes, as long as they fall within our certified range. Kindly furnish us with the specifications to enable us to assess and offer technical illustrations accordingly.

When it comes to reliable and versatile gas storage solutions, aluminum gas cylinders stand out as a top choice for a wide range of industries. As a leading supplier and manufacturer, our company is committed to providing high-quality aluminum gas cylinders that excel in both speciality and industrial applications. In this article, we’ll explore the advantages and various uses of these exceptional gas storage solutions.

Advantages of Aluminum Gas Cylinders:

- Lightweight Durability: Aluminum is renowned for its lightweight yet robust properties, making aluminum gas cylinders easy to handle and transport while maintaining their structural integrity even in challenging environments.

- Corrosion Resistance: One of the standout benefits of aluminum cylinders is their natural corrosion resistance. This quality ensures the cylinders’ longevity, making them suitable for various industries, including marine and offshore applications.

- High Thermal Conductivity: Aluminum’s excellent thermal conductivity enables efficient heat dissipation, reducing the risk of temperature-related complications during gas storage and transportation.

- Visual Inspection: Aluminum cylinders allow for visual inspection, providing users with a convenient way to assess the gas levels without compromising the cylinder’s integrity.

- Eco-Friendly Choice: Aluminum is a recyclable material, aligning with sustainable practices and environmental consciousness, making these cylinders an eco-friendly choice.

Versatile Uses in Specialty & Industrial Sectors:

- Medical & Healthcare: Aluminum gas cylinders play a crucial role in storing medical gases like oxygen and nitrogen, ensuring a reliable supply for hospitals, clinics, and emergencies.

- Welding & Cutting: Industries that require welding and cutting operations benefit from aluminum cylinders’ ability to store gases like acetylene, oxygen, and argon, ensuring precision and safety in these processes.

- Food & Beverage: In the food and beverage industry, aluminum cylinders store gases used for carbonation, creating fizzy beverages that consumers love.

- Laboratories: Research facilities and laboratories utilize aluminum cylinders for storing speciality gases essential for experiments and analysis.

- Aerospace: The aerospace sector relies on aluminum cylinders to house gases used in propulsion systems, onboard life support, and more.

- Industrial Manufacturing: From automotive to electronics, aluminum gas cylinders supply gases for various manufacturing processes, ensuring quality and efficiency.

Conclusion:

As a dedicated supplier and manufacturer of aluminum gas cylinders, our company is committed to delivering dependable solutions for speciality and industrial needs. The lightweight durability, corrosion resistance, and eco-friendly nature of these cylinders make them a versatile choice across a broad spectrum of applications. Whether in healthcare, manufacturing, or other sectors, aluminum gas cylinders are a reliable and efficient way to store and transport gases with confidence. Choose our company as your trusted partner for top-quality aluminum gas cylinders that meet the demands of your industry. Contact us today to learn more about how we can fulfil your gas storage requirements.

Aluminum Gas Cylinders Size

DOT 3AL Aluminum Gas Cylinder

| NO. | Outside Diameter | Service Pressure | Test pressure | Water Volume | Certified | Standard | Certification Body | ||||||

| Liters | lbs | ||||||||||||

| mm | in | bar | psi | bar | psi | min | max | min | max | ||||

| 1 | 50 | 1.97 | 250 | 3625 | 417 | 6042 | 0.26 | 0.46 | 0.57 | 1.01 | DOT | DOT 3AL | DOT |

| 2 | 60 | 2.36 | 166 | 2408 | 250 | 3626 | 0.35 | 0.65 | 0.77 | 1.43 | DOT | UN ISO7866 | DOT |

| 3 | 61 | 2.40 | 207 | 3000 | 345 | 5000 | 0.4 | 0.7 | 0.88 | 1.54 | DOT | DOT 3AL | DOT |

| 4 | 73.8 | 2.91 | 160 | 2321 | 200 | 2901 | 0.62 | 0.62 | 1.36 | 1.36 | DOT | DOT 39 | DOT |

| 5 | 73.8 | 2.91 | 120 | 1740 | 180 | 2611 | 0.2 | 1.5 | 0.44 | 3.31 | DOT | UN ISO11118 | DOT |

| 6 | 73.8 | 2.91 | 150 | 2176 | 225 | 3263 | 0.2 | 1.5 | 0.44 | 3.31 | DOT | UN ISO11118 | DOT |

| 7 | 81.5 | 3.21 | 153 | 2216 | 255 | 3694 | 0.6 | 1.3 | 1.32 | 2.87 | DOT | DOT 3AL | DOT |

| 8 | 81.5 | 3.21 | 124 | 1800 | 207 | 3000 | 0.63 | 1.17 | 1.39 | 2.58 | DOT | DOT 3AL | DOT |

| 9 | 90 | 3.54 | 207 | 3000 | 345 | 5000 | 0.92 | 1.68 | 2.03 | 3.70 | DOT | DOT 3AL | DOT |

| 10 | 111.3 | 4.38 | 139 | 2015 | 232 | 3359 | 1.2 | 2 | 2.65 | 4.41 | DOT | DOT 3AL | DOT |

| 11 | 111.3 | 4.38 | 124 | 1800 | 207 | 3000 | 0.98 | 1.82 | 2.16 | 4.01 | DOT | DOT 3AL | DOT |

| 12 | 111.3 | 4.38 | 139 | 2015 | 232 | 3359 | 2.52 | 4.68 | 5.56 | 10.32 | DOT | DOT 3AL | DOT |

| 13 | 133.4 | 5.25 | 153 | 2216 | 255 | 3694 | 3.9 | 7 | 8.60 | 15.43 | DOT | DOT 3AL | DOT |

| 14 | 133.4 | 5.25 | 124 | 1800 | 207 | 3000 | 2.38 | 4.42 | 5.25 | 9.74 | DOT | DOT 3AL | DOT |

TPED EN ISO7866 Aluminum Gas Cylinder

| NO. | Outside Diameter | Service Pressure | Test pressure | Water Volume | Certified | Standard | Certification Body | ||||||

| Liters | lbs | ||||||||||||

| mm | in | bar | psi | bar | psi | min | max | min | max | ||||

| 1 | 60 | 2.36 | 166 | 2408 | 250 | 3626 | 0.4 | 0.67 | 0.88 | 1.48 | TPED | EN ISO7866 | TUV |

| 2 | 60.5 | 2.38 | 200 | 2901 | 300 | 4351 | 0.35 | 0.7 | 0.77 | 1.54 | TPED | EN ISO7866 | TUV |

| 3 | 80 | 3.15 | 32 | 464 | 48 | 696 | 0.6 | 1.5 | 1.32 | 3.31 | TPED | EN ISO7866 | TI |

| 4 | 70 | 2.76 | 120 | 1740 | 180 | 2611 | 0.2 | 1.2 | 0.44 | 2.65 | TPED | EN ISO11118 | TUV |

| 5 | 73.8 | 2.91 | 120 | 1740 | 180 | 2611 | 0.2 | 1.3 | 0.44 | 2.87 | TPED | EN ISO11118 | TUV |

| 6 | 81.5 | 3.21 | 124 | 1798 | 186 | 2698 | 0.6 | 1.5 | 1.32 | 3.31 | TPED | EN ISO7866 | TUV |

| 7 | 90 | 3.54 | 200 | 2901 | 300 | 4351 | 0.7 | 1.6 | 1.54 | 3.53 | TPED | EN ISO7866 | TUV |

| 8 | 90 | 3.54 | 166 | 2408 | 250 | 3626 | 0.7 | 1.6 | 1.54 | 3.53 | TPED | EN ISO7866 | TUV |

| 9 | 111 | 4.37 | 124 | 1798 | 186 | 2698 | 1.4 | 3.9 | 3.09 | 8.60 | TPED | EN ISO7866 | TUV |

| 10 | 111 | 4.37 | 200 | 2901 | 300 | 4351 | 1.4 | 4 | 3.09 | 8.82 | TPED | EN ISO7866 | TUV |

| 11 | 120 | 4.72 | 166 | 2408 | 250 | 3626 | 1.4 | 4.5 | 3.09 | 9.92 | TPED | EN ISO7866 | TUV |

| 12 | 140 | 5.51 | 166 | 2408 | 250 | 3626 | 4 | 8 | 8.82 | 17.64 | TPED | EN ISO7866 | TUV |

| 13 | 140 | 5.51 | 200 | 2901 | 300 | 4351 | 3 | 9 | 6.61 | 19.84 | TPED | EN ISO7866 | TUV |

| 14 | 184 | 7.24 | 166 | 2408 | 250 | 3626 | 6 | 15 | 13.23 | 33.07 | TPED | EN ISO7866 | TUV |

| 15 | 184 | 7.24 | 200 | 2901 | 300 | 4351 | 6 | 16 | 13.23 | 35.27 | TPED | EN ISO7866 | TUV |

| 16 | 203 | 7.99 | 166 | 2408 | 250 | 3626 | 11 | 20 | 24.25 | 44.09 | TPED | EN ISO7866 | TUV |

GB/T 11640 Aluminum Gas Cylinder

| NO. | Outside Diameter | Service Pressure | Test pressure | Water Volume | Certified | Standard | Certification Body | ||||||

| Liters | lbs | ||||||||||||

| mm | in | bar | psi | bar | psi | min | max | min | max | ||||

| 1 | 60 | 2.36 | 150 | 2176 | 225 | 3263 | 0.2 | 0.6 | 0.44 | 1.32 | TS | GB/T 11640 | TS |

| 2 | 60 | 2.36 | 300 | 4351 | 450 | 6527 | 0.2 | 0.5 | 0.44 | 1.10 | TS | GB/T 11640 | TS |

| 3 | 81.5 | 3.21 | 150 | 2176 | 225 | 3263 | 0.7 | 1.5 | 1.54 | 3.31 | TS | GB/T 11640 | TS |

| 4 | 111.3 | 4.38 | 200 | 2901 | 300 | 4351 | 1.1 | 4 | 2.43 | 8.82 | TS | GB/T 11640 | TS |

| 5 | 140 | 5.51 | 150 | 2176 | 225 | 3263 | 3 | 9 | 6.61 | 19.84 | TS | GB/T 11640 | TS |

| 6 | 140 | 5.51 | 200 | 2901 | 300 | 4351 | 3 | 9 | 6.61 | 19.84 | TS | GB/T 11640 | TS |

| 7 | 184 | 7.24 | 200 | 2901 | 300 | 4351 | 6 | 15 | 13.23 | 33.07 | TS | GB/T 11640 | TS |

| 8 | 203 | 7.99 | 150 | 2176 | 225 | 3263 | 8 | 20 | 17.64 | 44.09 | TS | GB/T 11640 | TS |