Aluminum CO2 Cylinder

- Standard: DOT, TPED, GB/T

- Material: aluminium alloy 6061-T6

- Applications: CO2, dispensing carbonated soft drinks, beer, and other beverages.

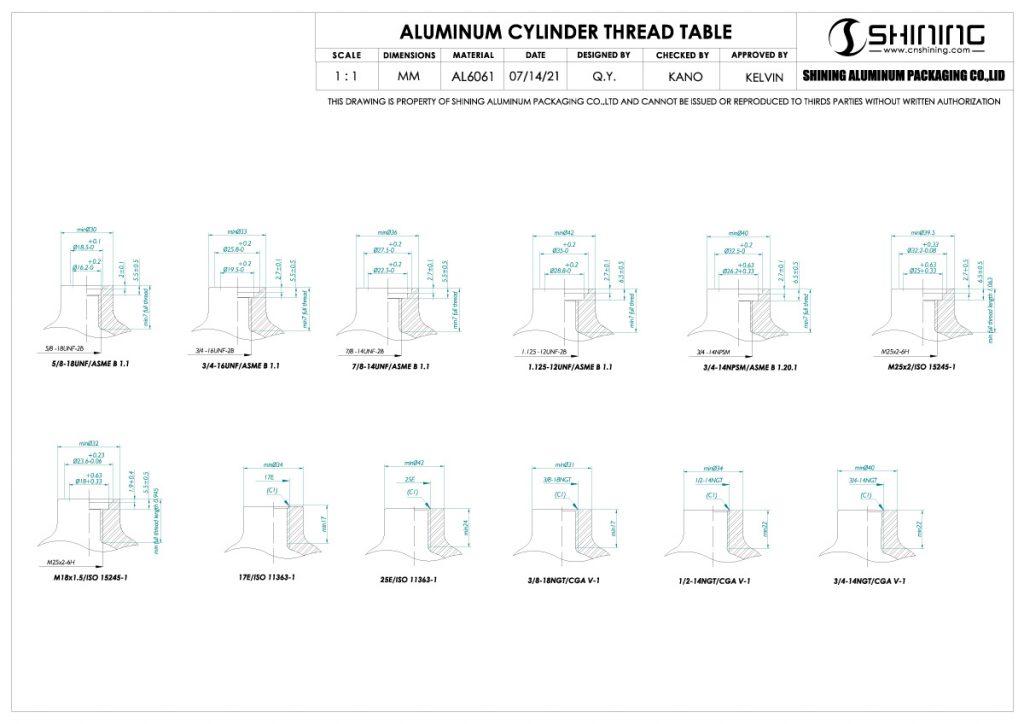

- Valve & Thread: Specified & Installed Upon Request

- Size: Custom Size is available with the TPED/DOT Certified Range

- Finish: Unpainted & Brushed & Different Color Coated

- Cleaning: Food Grade Cleaning by Ultrasonic Cleaners

- Delivery time: Usually 30-40 days Upon Quantity

Our lightweight, durable and corrosion-resistant CO2 cylinders are the optimal choice for commercial beverage dispensing from soft drinks to craft beers.

- Material: We utilize a spectrum analyzer to ensure the stability of the material for aluminium CO2 cylinders, which are composed of aluminium alloy 6061-T6.

- Surface Finish: We offer a range of customization possibilities for the surface finish of aluminium cylinders. These options include polishing, body painting, and more.

- Food-Grade Cleaning: Utilizing ultrasonic cleaners, a process of food-grade cleaning is employed. The interior and exterior of the cylinders undergo meticulous purification with pristine water at a temperature of 70 degrees Celsius. This rigorous procedure guarantees the suitability of the products for consumption in the food and beverage industry.

- Automatic Production: Utilizing automatic shaping machinery ensures the seamless refinement of cylinder interfaces, consequently elevating their safety quotient.

- Size Customizing: We welcome orders for customized sizes, as long as they fall within our certified range. Kindly furnish us with the specifications to enable us to assess and offer technical illustrations accordingly.

In the world of beverage carbonation, the choice of equipment plays a pivotal role in ensuring a consistent and refreshing experience. Enter the versatile and efficient Aluminum CO2 Cylinder – the perfect companion for all your carbonation needs. As a leading supplier and manufacturer in the industry, our company takes pride in offering a comprehensive range of CO2 bottles, cartridges, tanks, and canisters to elevate your beverage game.

Unveiling the Advantages

Exceptional Purity and Quality: Our Aluminum CO2 Cylinders are crafted with precision to guarantee the utmost purity and quality of the gas they contain. This results in sparkling beverages that maintain their original flavours without any unwanted aftertaste.

Durability Redefined: Engineered using state-of-the-art technology, our CO2 cylinders boast unparalleled durability. Constructed from premium aluminum, they are rust-resistant and designed to withstand the rigours of extended usage, ensuring a long product lifespan.

Portability and Convenience: Whether you’re a commercial establishment or a home enthusiast, our CO2 cartridges offer unparalleled portability and convenience. Compact yet powerful, they can be easily transported and utilized for various applications, making them an ideal choice for outdoor events and on-the-go carbonation.

Efficient Gas Storage: Our CO2 tanks come in various sizes to suit your specific requirements. The efficient gas storage capabilities ensure you have an uninterrupted supply of carbon dioxide, enabling you to carbonate a wide range of beverages without the hassle of frequent replacements.

Environmentally Friendly: Choosing aluminum cylinders demonstrates your commitment to sustainability. Aluminum is highly recyclable, making our cylinders an eco-friendly choice that aligns with modern environmental standards.

Versatile Applications

Beverage Carbonation: Our Aluminum CO2 Cylinders are the backbone of beverage carbonation, whether you’re adding bubbles to water, soda, beer, or cocktails. Achieve the perfect fizz and mouthfeel that customers and guests crave.

Food Preservation: CO2 canisters are not limited to beverages. They are also used for food preservation, preventing oxidation and extending the shelf life of packaged food products.

Medical and Industrial Uses: Beyond the culinary world, CO2 cylinders have essential medical and industrial applications. From medical gases to welding and fire suppression, our cylinders serve diverse purposes.

Conclusion

Elevate your beverage experience with our cutting-edge Aluminum CO2 Cylinder solutions. As a prominent supplier and manufacturer in the industry, we pride ourselves on delivering excellence in quality, durability, and performance. Whether you’re in the business of beverages, or food, or require CO2 for specialized applications, our range of CO2 bottles, cartridges, tanks, and canisters has you covered. Choose innovation, choose reliability – choose our Aluminum CO2 Cylinders.

Aluminum CO2 Cylinders Size

DOT 3AL Aluminum Gas Cylinder

| NO. | Outside Diameter | Service Pressure | Test pressure | Water Volume | Certified | Standard | Certification Body | ||||||

| Liters | lbs | ||||||||||||

| mm | in | bar | psi | bar | psi | min | max | min | max | ||||

| 1 | 50 | 1.97 | 250 | 3625 | 417 | 6042 | 0.26 | 0.46 | 0.57 | 1.01 | DOT | DOT 3AL | DOT |

| 2 | 60 | 2.36 | 166 | 2408 | 250 | 3626 | 0.35 | 0.65 | 0.77 | 1.43 | DOT | UN ISO7866 | DOT |

| 3 | 61 | 2.40 | 207 | 3000 | 345 | 5000 | 0.4 | 0.7 | 0.88 | 1.54 | DOT | DOT 3AL | DOT |

| 4 | 73.8 | 2.91 | 160 | 2321 | 200 | 2901 | 0.62 | 0.62 | 1.36 | 1.36 | DOT | DOT 39 | DOT |

| 5 | 73.8 | 2.91 | 120 | 1740 | 180 | 2611 | 0.2 | 1.5 | 0.44 | 3.31 | DOT | UN ISO11118 | DOT |

| 6 | 73.8 | 2.91 | 150 | 2176 | 225 | 3263 | 0.2 | 1.5 | 0.44 | 3.31 | DOT | UN ISO11118 | DOT |

| 7 | 81.5 | 3.21 | 153 | 2216 | 255 | 3694 | 0.6 | 1.3 | 1.32 | 2.87 | DOT | DOT 3AL | DOT |

| 8 | 81.5 | 3.21 | 124 | 1800 | 207 | 3000 | 0.63 | 1.17 | 1.39 | 2.58 | DOT | DOT 3AL | DOT |

| 9 | 90 | 3.54 | 207 | 3000 | 345 | 5000 | 0.92 | 1.68 | 2.03 | 3.70 | DOT | DOT 3AL | DOT |

| 10 | 111.3 | 4.38 | 139 | 2015 | 232 | 3359 | 1.2 | 2 | 2.65 | 4.41 | DOT | DOT 3AL | DOT |

| 11 | 111.3 | 4.38 | 124 | 1800 | 207 | 3000 | 0.98 | 1.82 | 2.16 | 4.01 | DOT | DOT 3AL | DOT |

| 12 | 111.3 | 4.38 | 139 | 2015 | 232 | 3359 | 2.52 | 4.68 | 5.56 | 10.32 | DOT | DOT 3AL | DOT |

| 13 | 133.4 | 5.25 | 153 | 2216 | 255 | 3694 | 3.9 | 7 | 8.60 | 15.43 | DOT | DOT 3AL | DOT |

| 14 | 133.4 | 5.25 | 124 | 1800 | 207 | 3000 | 2.38 | 4.42 | 5.25 | 9.74 | DOT | DOT 3AL | DOT |

TPED EN ISO7866 Aluminum Gas Cylinder

| NO. | Outside Diameter | Service Pressure | Test pressure | Water Volume | Certified | Standard | Certification Body | ||||||

| Liters | lbs | ||||||||||||

| mm | in | bar | psi | bar | psi | min | max | min | max | ||||

| 1 | 60 | 2.36 | 166 | 2408 | 250 | 3626 | 0.4 | 0.67 | 0.88 | 1.48 | TPED | EN ISO7866 | TUV |

| 2 | 60.5 | 2.38 | 200 | 2901 | 300 | 4351 | 0.35 | 0.7 | 0.77 | 1.54 | TPED | EN ISO7866 | TUV |

| 3 | 80 | 3.15 | 32 | 464 | 48 | 696 | 0.6 | 1.5 | 1.32 | 3.31 | TPED | EN ISO7866 | TI |

| 4 | 70 | 2.76 | 120 | 1740 | 180 | 2611 | 0.2 | 1.2 | 0.44 | 2.65 | TPED | EN ISO11118 | TUV |

| 5 | 73.8 | 2.91 | 120 | 1740 | 180 | 2611 | 0.2 | 1.3 | 0.44 | 2.87 | TPED | EN ISO11118 | TUV |

| 6 | 81.5 | 3.21 | 124 | 1798 | 186 | 2698 | 0.6 | 1.5 | 1.32 | 3.31 | TPED | EN ISO7866 | TUV |

| 7 | 90 | 3.54 | 200 | 2901 | 300 | 4351 | 0.7 | 1.6 | 1.54 | 3.53 | TPED | EN ISO7866 | TUV |

| 8 | 90 | 3.54 | 166 | 2408 | 250 | 3626 | 0.7 | 1.6 | 1.54 | 3.53 | TPED | EN ISO7866 | TUV |

| 9 | 111 | 4.37 | 124 | 1798 | 186 | 2698 | 1.4 | 3.9 | 3.09 | 8.60 | TPED | EN ISO7866 | TUV |

| 10 | 111 | 4.37 | 200 | 2901 | 300 | 4351 | 1.4 | 4 | 3.09 | 8.82 | TPED | EN ISO7866 | TUV |

| 11 | 120 | 4.72 | 166 | 2408 | 250 | 3626 | 1.4 | 4.5 | 3.09 | 9.92 | TPED | EN ISO7866 | TUV |

| 12 | 140 | 5.51 | 166 | 2408 | 250 | 3626 | 4 | 8 | 8.82 | 17.64 | TPED | EN ISO7866 | TUV |

| 13 | 140 | 5.51 | 200 | 2901 | 300 | 4351 | 3 | 9 | 6.61 | 19.84 | TPED | EN ISO7866 | TUV |

| 14 | 184 | 7.24 | 166 | 2408 | 250 | 3626 | 6 | 15 | 13.23 | 33.07 | TPED | EN ISO7866 | TUV |

| 15 | 184 | 7.24 | 200 | 2901 | 300 | 4351 | 6 | 16 | 13.23 | 35.27 | TPED | EN ISO7866 | TUV |

| 16 | 203 | 7.99 | 166 | 2408 | 250 | 3626 | 11 | 20 | 24.25 | 44.09 | TPED | EN ISO7866 | TUV |

GB/T 11640 Aluminum Gas Cylinder

| NO. | Outside Diameter | Service Pressure | Test pressure | Water Volume | Certified | Standard | Certification Body | ||||||

| Liters | lbs | ||||||||||||

| mm | in | bar | psi | bar | psi | min | max | min | max | ||||

| 1 | 60 | 2.36 | 150 | 2176 | 225 | 3263 | 0.2 | 0.6 | 0.44 | 1.32 | TS | GB/T 11640 | TS |

| 2 | 60 | 2.36 | 300 | 4351 | 450 | 6527 | 0.2 | 0.5 | 0.44 | 1.10 | TS | GB/T 11640 | TS |

| 3 | 81.5 | 3.21 | 150 | 2176 | 225 | 3263 | 0.7 | 1.5 | 1.54 | 3.31 | TS | GB/T 11640 | TS |

| 4 | 111.3 | 4.38 | 200 | 2901 | 300 | 4351 | 1.1 | 4 | 2.43 | 8.82 | TS | GB/T 11640 | TS |

| 5 | 140 | 5.51 | 150 | 2176 | 225 | 3263 | 3 | 9 | 6.61 | 19.84 | TS | GB/T 11640 | TS |

| 6 | 140 | 5.51 | 200 | 2901 | 300 | 4351 | 3 | 9 | 6.61 | 19.84 | TS | GB/T 11640 | TS |

| 7 | 184 | 7.24 | 200 | 2901 | 300 | 4351 | 6 | 15 | 13.23 | 33.07 | TS | GB/T 11640 | TS |

| 8 | 203 | 7.99 | 150 | 2176 | 225 | 3263 | 8 | 20 | 17.64 | 44.09 | TS | GB/T 11640 | TS |