- Material: 99.7% aluminum

- Capacity(ml): 200ml,500ml

- Diameter(mm): 51mm,60mm

- Height(mm): 76mm,130mm

- Thickness(mm): 0.2-0.3

- Surface finish: Polishing, Color painting, Anodizing

- MOQ: 5,000 PCS

- Usage: Water, Beer, Vodka, Spirit, Whisky, Brandy, Coffee

Custom aluminum Cup with different shapes & printings

- Material: 99.7% aluminum

- Capacity(ml): 100-1000

- Diameter(mm): 35-95

- Height(mm): 66-180

- Thickness(mm): 0.5-0.6

- Surface finish: Polishing, Color painting, Anodizing

- MOQ: 5,000 PCS

- Usage: Water, Beer, Vodka, Spirit, Whisky, Brandy, Coffee

- Material: 99.7% aluminum

- Capacity(ml): 600

- Diameter(mm): 66

- Height(mm): 165

- Thickness(mm): 0.4-0.5

- Surface finish: Polishing, Offset printing

- MOQ: 50,000 PCS

- Usage: Water, Beer, Coffee

Introduction

If you are looking for aluminum cups, you must read this post. This post contains all the information about aluminum cups.

What is an aluminum cup?

Aluminum cup is a cup made of aluminum (or aluminium, in British English). At some pace, it is also referred to as aluminum tumblers, alu cups, aluminum glasses.

There are different types of cups; you can find out glass cups, plastic cups, paper cups, but the best option for your drinking are aluminum cups.

What material aluminum cup made?

Aluminum cups are usually made with 1070 aluminum which is widely used in aluminum bottles, have great performance on corrosion prevention, recyclable, eco-friendly, 100% comply with food contact regulation of FDA(USA) and LFGB(EU).

What is the purpose of aluminum cups?

- aluminum drinking cups

- aluminum coffee cups

- aluminum beer cups

- aluminum cola cup

- aluminum coffee cup

- aluminum cups camping

- aluminum party cups

- aluminum cup super bowl

What is ball aluminum cup?

As mentioned, ball aluminum cups are safer cups than plastic cups or bottles. Some ball aluminum cups with lids

This material is approved by the FDA to be a kind of container. And that is because they are recyclable, and the material won’t cause any bad effects on your health, especially when you fill them with water that you will be using for drinking.

Ball aluminum solo cup

Ball aluminum cup vs solo cup can confuse you. Every cup has its solo cup size. In the same way, ball aluminum has a solo cup too. This is their 16 flz cup.

It might be small for you but it is safe to drink and even cook on an aluminum solo cup. It has many uses despite its size, you can even put your food there. And it will remain safe.

Ball aluminum cup sizes

As mentioned, they are available in handheld sizes. The most common is the 16 fl oz aluminum cup followed by the 20 fl oz.

Ball aluminum cup commercial

The actor that is behind the famous Aquaman role has endorsed ball aluminum cup, Jason Momoa. In his commercial, you will notice an aluminum cup logo at the ball aluminum cup super bowl.

His commercial suits ball aluminum cup well because it is primarily made for water. Moreover. Aquaman came from is the Hero of the warers, right?

Ball aluminum cups price

If you wonder how much ball aluminum cups cost, it depends on the size and the manufacturer. However, they are affordable.

For example, the ball aluminum cup cost of 20 fl oz cup is only $25 in Amazon. That is already set by 10. This means that one ball aluminum cup roughly cost 2.5 USD.

While the 16 oz of ball aluminum cup cost $13.99 24 which is available on kegworks too.

Where can I buy ball aluminum cups

You can buy them at any convenience store near you. Or just search in Google for the “Ball aluminum cups near me.” But Ball aluminum cups Walmart is much recommended due to their availability. This is also the same as a ball aluminum cup target and a ball aluminum cup on Amazon. You can easily find them because they are accessible.

They are also available in our shop. Because you can just have them from anywhere it is important that you watch a ball aluminum review to help you get a better deal.

Ball recyclable aluminum cups

Ball Aluminium cups can be used as disposable cups too. However, they are more known as reusable because that is really their function. After all, it is not nice for recyclable cups to get thrown away when they should be recycled.

For a short answer to the question, if you can reuse a ball of aluminum cups, yes, you can. As long as their shape is still intact they will cause no problem.

Why are aluminum cups better than plastic?

Since people continue to become more environmentally conscious and more health-minded, the use of aluminum cups grows fast. Safer and more durable for the environment than plastic cups, aluminum cups offer a sanitary and safe alternative for beer and other beverages. The chemicals used to make plastic cups, such as BPA come with a cost to your health. Not so with aluminum cups, which are chemical-free and highly durable. One aluminum cup can last for years and take the place of thousands of disposable plastic cups, and these plastic cups will eventually enter our oceans and landfills.

What are the types of aluminum cups?

According to the times of use, aluminum cups can be divided into two types, disposable aluminum cups, and reusable aluminum cups.

Disposable aluminum cups are very thin(0.2mm), can be directly squashed for recycling after use. Reusable aluminum cups are thick(0.5-1mm), can be used for several years. This type of aluminum cup includes

- aluminum solo cup

- vintage aluminum cups

- aluminum cups from the 50s

- 70’s aluminum cups

- aluminum mixing cups

- anodized aluminum drinking cups

- colored aluminum cups

- retro aluminum tumblers

Are the new aluminum cups recyclable?

After being used, an aluminum cup can be recycled and returned as a new cup or can in just 60 days after being used. It can also be recycled to take on a new life as a car, laptop, or bicycle.

Which brands are using aluminum cups?

The world’s well-known brands that use aluminum cups are

- Coca-Cola Aluminum Cup

- Coors light aluminum cup

- Bud light aluminum cups

- Budweiser aluminum cup world cup

Do aluminum cups keep drinks colder?

Aluminum has a higher heat transfer rate than iron, which is why it’s common to use aluminum cups for beers. As a result, aluminum cups are suitable for cold drink containers, such as beer and beverages. Aluminum cups could keep drinks colder.

Is it safe to drink out of aluminum cups?

Are aluminum cups safe to drink from? Is drinking from aluminum cups safe?

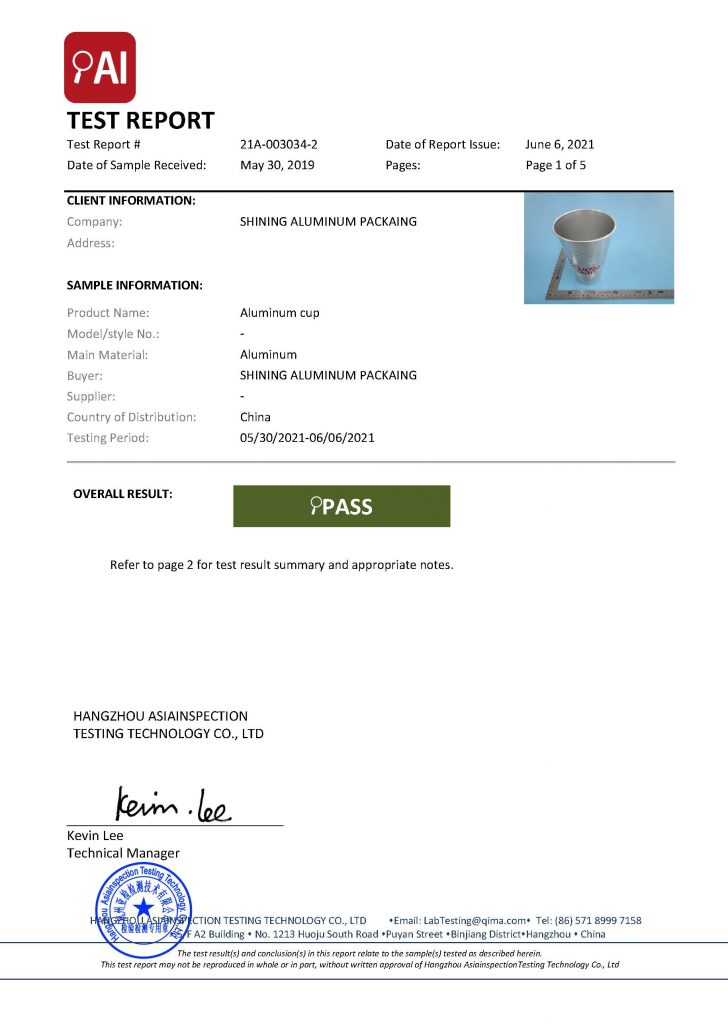

We often receive such problems. Of course, it is safe to use aluminum cups. We have three methods to ensure the safety of aluminum cups

- Our cup has a BPA-free protective liner.

- We use a food-grade anodized process.

- We often send samples to a third-party laboratory for testing, such as SGS & TUV.

Here is our test results summary:

Aluminum cup near me – aluminum cup where to buy?

You can buy aluminum cups from local shops, Amazon, Walmart for your family, camping, office drinking.

As a company that runs a business with aluminum cup products, wholesalers, or private brands, you buy wine tumbler products and contact supplies like “SHINING” which specializes in aluminum cup OEM manufacturing for your custom design aluminum cup projects.

Where is an aluminum cup made?

More than 90% of the world’s aluminum cups are made in China. Why not be made in the USA?

- The raw material of aluminum

China has the biggest production output for aluminum material to have competitive costs.

- Lack of skilled manufacturing engineers and workers

The aluminum cup manufacturing production relies on a lot of workers and experience engineer support. However, automation equipment can replace workers. It needs a big investment at the beginning, and big volume order quantities support the constant production.

- Strict environment policy

the aluminum cup is reusable, environmentally, and eco friendly, but the manufacturing processes related to anodized, polishing, and painting, all these manufacturing processes have pollution, which is impossible to have a manufacturing facility in the USA.

In summary, it’s impossible to have aluminum cups made in the USA, since cost, efficiency, labor, environment, even it is not made in China, still will make in other countries, not made in the USA anyway.

Aluminum cup manufacturing processes

There are three production processes for aluminum cups, mainly including

spinning forming process, cupping press, impact extrusion process. Let’s have a look. It may be simpler than you think.

pinning forming produce

1. Purchasing raw material

There are three series of aluminum materials for making aluminum cups, 1060 series, 1070 series, and 1090 series. The raw materials we use are 1070 series and 1090 series, which can meet food-grade requirements. Some factories also use the 1060 series, but this series is not pure enough and can’t meet the food grade requirement. We have used them before, but the products made are of poor quality. Now we only use the 1070 series and 1090 series. These are purer and more environmentally friendly and are the designated standards of the Coca-Cola Company.

The thickness of the material is generally 0.5-1mm. Thick materials don’t require a curling process, but the processing speed is slow, and the cost is high. Thin materials can be produced quickly but need to curl to prevent scratching the mouth.

2. Stamping

Stamping means that aluminum plates are stamped into wafers. After buying the raw materials, we need to cut the raw material into the required size right. We will use the stamping machine for the wafers. The stamping machine is to cut it into this size because we have different sizes and different cups. This wafer can transform into a cup, and the other different designs require different kinds of wafers to be transformed into that particular design.

The stamping machine is divided into two parts. One is the automatic stamping machine, and the other one is the manual stamping machine. The automatic stamping machine has good efficiency, and the manual stamping machine is too slow, so now we only use the automatic stamping machine, which greatly improves the generation efficiency. It can stamp three wafers every time. Every stamping machine can stamp about 15,000 pcs of wafers every day.

3. Making the mold

We use CNC machines to make the mold. The appearance of the mold is like a solid cup. If there is any texture or pattern requirement, we also need to do that on the mold.

4. Spinning forming

We can use the wafer to produce the shape of a cup. The steps are as follows: First, we put the wafer on the spinning machine and use the cutter head to shape the wafer. Then use a flat knife to emboss. If there is no pattern requirement, smooth it. Finally, we use a sharp knife to trim the edges to make sure that the edges are always smooth because when we are drinking around our mouth, we need it to be very smooth. Then we will get the original cup.

We use the automatic machine to spin the cup. The automatic machine can replace the manual completion of some simple and repetitive actions and complex procedures. Loading and unloading, material grabbing, material transferring, and automatic assembly are all processes automatic machines can now complete. Our automated machine automatically grabs the aluminum cup, transfers it to the spinning machine, and automatically places the aluminum cup after spinning forming. The whole process does not require manual operation. Every spinning forming machine can produce 1500 cups per day.

5. Polishing

Polishing is a procedure to make aluminum cups brighter, shining, and with no oil. We will polish the mouth of the cup, the surface, and the bottom. The polishing process is critical because that will polish the oil we no longer see on the cup.

6. Anodized

Put the aluminum cup into the anodized pool, aluminum coated with a protective oxide layer by an electrolytic process in which the metal forms the anode. Standard anodized colors are gold, blue, green, red, etc. The inside and outside of the anodized cup are the same color.

7. Decoration

We will use the most suitable printing process according to the shape of the aluminum cup and the design, such as water transfer, heat transfer printing, laser engraving, silk-screen printing, pad printing, and laser.

8. Inspecting

Mainly inspect the appearance, burrs, lines, etc. The appearance should be free from scratches on the surface. Burr, no burr on the cup mouth. Good products are smooth and shiny, the texture on the surface is neat and clear, But the defective product is a bit scratchy. No deformed places, just around. Then check the color and printing, no leakage, the color difference.

Impact extrusion produce

The impact extrusion process is similar to the aluminum bottle production process. Please check our aluminum bottle process. The thickness of these cups is 0.4-0.5mm.

1.raw material(aluminum slug) → 2. Impact Extrusion Presses → 3. Trimming and Brushing → 4. Transfer → 5. Washing → 6. Drying → 7. Iner Coating → 8. Base Coting → 9. Offset Printing → 10. Top Coating → 11. Necking → 12. Inspecting

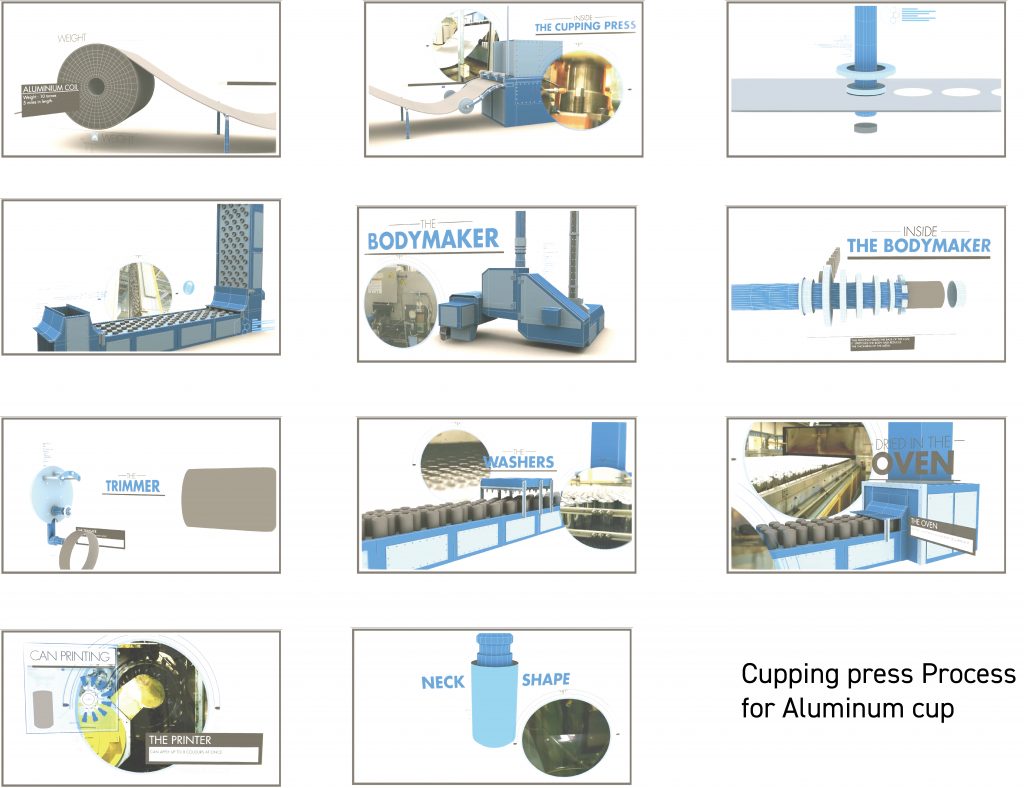

Cupping press produce

The stamping process is similar to aluminum beverage can. The thickness of these processes is about 0.2mm.

1.Raw material(aluminum coil) → 2. Cupping press → 3. Bodymaker → 4. Trimmer → 5. Washing → 6. Drying → 7. Offset Printing → 10. Top Coating → 11. Necking → 12. Inspecting

The following table compares the differences between the three production processes. Contact us to find more detail for aluminum cups.

Spinning forming | Impact extrusion | Cupping press | |

MOQ | 1000 pcs | 50,000 pcs | 200,000 pcs |

Price | $3 | $1 | $0.6 |

Mold Price | $500 | $20,000-$50,000 | $500,000-$1000,000 |

Productivity (Day) | 10,000 PCS | 100,000 PCS | 500,000 PCS |

Thickness | 0.5-1mm | 0.4mm | 0.2mm |

Times of use | Many times | Many times | Disposable |

Printing | Complex pattern | Complex pattern | Simple pattern |

Aluminum Cup Price – How much does an aluminum cup cost?

When you want to create a custom design aluminum cup, you should know how much it costs to manufacture a cup and what can affect the cost?

In this situation, you are in the right place here that SHINING Aluminum packaging can help you find out the vital thing you should know about aluminum cup manufacturing prices costs.

The aluminum cup cost can be very different depending on your custom parts design and the order quantities.

1. Material: aluminum

For example, product design cost will begin when you set up the project even if it does not start production; your material cost is often given per g. It’s important to know there would be a material waste at the beginning of each production, which means your order quantities are bigger. The average waste of raw material for each product is less.

2. The cost of different order quantities

The order quantities have a big impact on production manufacturing costs. The bigger volume of your aluminum cups order quantities, the more price you can save.

You can save shipment costs a lot by different quantities.

For a standard size 17oz/500ml aluminum cup, you can choose shipment as follow;

less than 100pcs; Express delivery, fast but expensive

100~3000 pcs; sea shipment slow and expensive

2000 pcs; sea shipment FCL 20″ GP container, slow and cheap

40000 pcs; sea shipment FCL 40″ GP container, slow and very cheap

3. The timing of your order

When your aluminum cup order quantities are small, the prices would be higher than usual with urgent time.

When your order is one-time, and with urgent time, the prices would be higher than usual.

4. The cost of different surface finish:

We can do different custom surface treatments for your aluminum cups depending on your design needs.

There’s no plate charge when you only want to apply different Pantone colors with painting or anodized.

It would have a plate fee cost when you want to have different graphic decorations for your custom design cup with different techniques, such as logo printing, logo embossing, heat transfer printing, silk printing, offset printing, pad printing, etc.

The plate charge cost will start from $30 to $600, sample lead time from 7 days to 15 days.

5. Labour cost

The labor cost does keep increasing year by year. We need to think of the labor cost from the cup design to reduce the product unit cost by the useless hand-made manufacturing process.

6. Additional cost

Packaging cost; with some unique products which need a custom design packaging will cause an additional cost.

How to personalize aluminum cups?- Custom aluminum cups

You may want to personalized aluminum cups to have unique colors, logos, printings.

There are many different ways to personalize your aluminum cups. Let’s have a close look at how to make it works. It may be much easier and more accessible than you may think.

Custom size and shape of a new mold aluminum cup with a unique shape would be your custom mold with exclusive manufacturing with SHINING.

Confirm the Pantone color number of custom color and the surface finishing for your custom aluminum cup, such as anodized, spray painting, etc. You can send some photos for our sales to confirm what is the surface treatment exactly.

Design your custom artwork for your cups with CorelDRAW or Illustrator format document. We will confirm the logo placement, sizes, and technique you want to make your custom logo, such as silk screen printing, heat transfer printing, and offset printing. We check if it can be manufactured and what technique is most economical with the best quality, then confirm back sample plate charge cost, sample lead time, product unit cost, production lead time.

You may have more different requirements to personalize your aluminum cups, to create a unique custom shape or a custom paper box for your brand, you can contact a china aluminum cup manufacturer supplier or aluminum cups wholesale like “SHINING aluminum packaging” who is specialized in aluminum cups OEM/ODM/OPM manufacturing from concept design, Mold development, mass production to final shipment to grow your brand from “0” to market.

OEM Manufacturing Processes

Step 1: Inquiry

Choose the aluminum cup you are interested in and send us your detailed requirements, such as product pictures, colors, signs, packaging, quantity, etc. Our sales support team will respond to you within 24 hours from Monday to Friday.

Step 2: Non-Disclose Agreement (NDA)

When you want to develop custom-designed aluminum cups related to confidential information (drawing paper, design concepts), we will sign an NDA with you before discussing any details.

Step 3: Quotation & Sample

We quoted prices & lead time for product or tooling after collecting all required information from you, can offer free samples for stock items, custom logo & color sample would charge cost and usually, seven days, tooling & sample lead time takes 30 working days.

Step 4. Production & Inspection

After receiving the deposit payment, we start mass production, which usually takes 30 days’ lead time. Our quality department conducts in-process inspection and tests during mass production and has a final pre-shipment inspection for customer review.

Step 5. Final Payment & Shipment

After receiving the final payment, we will cooperate with your forwarder to book the shipment. Cargo will arrive at your warehouse around ten days by air shipment 40 days by sea shipment.

How to clean aluminum cups with smell problems?

When you find an aluminum cup that smells terrible, you will want to know why it smells. You want to find a way to remove the smell in the aluminum cup.

Why does it smell?

When you drink with beer, juice liquid with your aluminum cups, you might be lazy to wash it immediately, leave it alone for a couple of days. Then you will find the cup is smell strongly.

This is because after you drink the beverage, microorganisms will multiply in it. There will be a few microorganisms at the beginning. For a couple of days, they will reproduce from generation to generation, and their metabolites will have a variety of flavors.

How to clean

1. Washing cup body with salt or detergents:

If you want the aluminum cup to be cleaned and sterilized, you only need three steps. The first step is to pour some or detergents into the cups. Then add warm water to the cups and wipe with your hands. Pour out the dirt inside and rinse it again with clean water at last.

2. Clean the cup mouth with toothpaste

After cleaning the inner of cups, let’s clean the mouth of the cup. Because the cup’s mouth is often in direct contact with our mouth, it is easy to bring bacteria into the body and harm our health if it is not cleaned. Therefore, when cleaning the mouth of the cup, apply some toothpaste to the cup’s mouth. Brush again with a toothbrush. Because the toothpaste contains abrasives that can remove stains on the mouth of the aluminum cup, after cleaning the mouth of the cup, in this way, the cleaned cup is as clean as new and has no bacteria, which completely solves the smells for the aluminum cups.

Can you put aluminum cups in the dishwasher?

We don’t recommend putting the aluminum cup in the dishwasher because high temperatures will damage the aluminum cup’s internal coating and external printing. If you have a dishwasher requirement, don’t hesitate to get in touch with us, we will use a unique process to treat the aluminum cup to ensure that it passes the dishwasher test.