Aluminum Gas Cylinders for Life Support

- Standard: DOT, TPED, GB/T

- Material: aluminum alloy 6061-T6

- Applications: firefighters and first responders

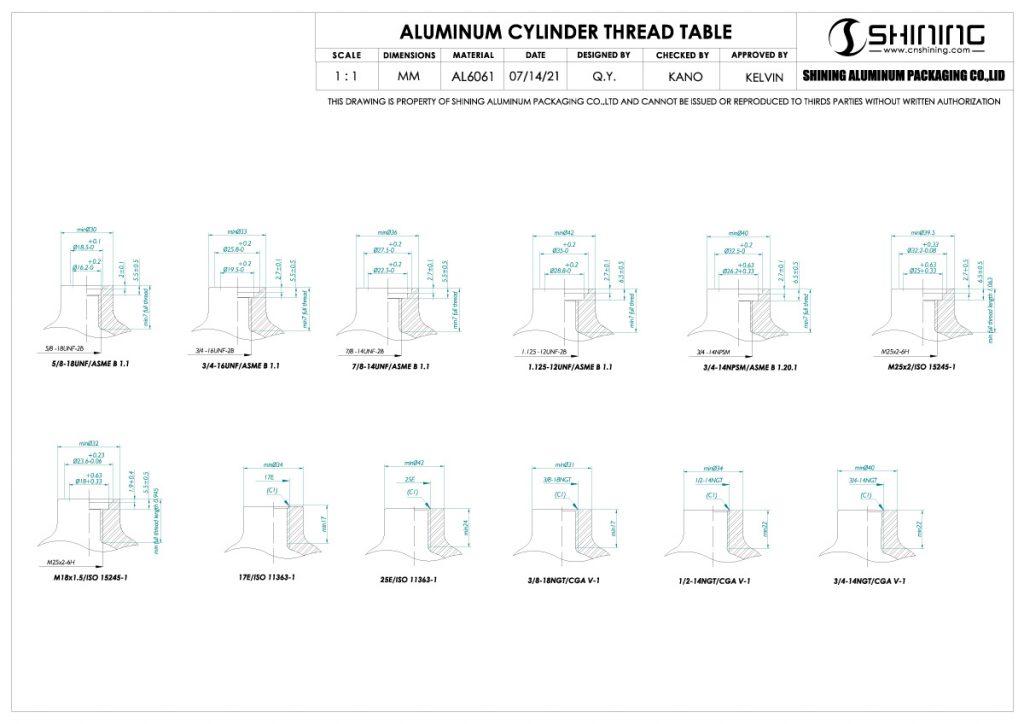

- Valve & Thread: Specified & Installed Upon Request

- Size: Custom Size is available with the TPED/DOT Certified Range

- Finish: Unpainted & Brushed & Different Color Coated

- Cleaning: Cleaning by Ultrasonic Cleaners

- Delivery time: Usually 30-40 days Upon Quantity

We manufacture lightweight cylinders that increase speed and mobility for firefighters and first responders and provide reliability and durability in hazardous industrial situations and during emergencies requiring breathing support.

- Material: We utilize a spectrum analyzer to ensure the stability of the material for aluminium gas cylinders, which are composed of aluminium alloy 6061-T6.

- Surface Finish: We offer a range of customization possibilities for the surface finish of aluminium cylinders. These options include polishing, body painting, and more.

- Automatic Production: Utilizing automatic shaping machinery ensures the seamless refinement of cylinder interfaces, consequently elevating their safety quotient.

- Size Customizing: We welcome orders for customized sizes, as long as they fall within our certified range. Kindly furnish us with the specifications to enable us to assess and offer technical illustrations accordingly.

When it comes to life support systems, the choice of equipment is crucial for ensuring safety and reliability. Aluminum gas cylinders have emerged as an indispensable component in various life support applications due to their exceptional qualities. As a leading supplier and manufacturer in the industry, our company is dedicated to providing top-notch aluminum gas cylinders that meet the highest standards of quality and performance.

The Advantages of Aluminum Gas Cylinders

- Lightweight and Durable: Aluminum gas cylinders are renowned for their lightweight yet durable construction. This makes them easy to handle and transport, a vital feature in critical life support scenarios.

- Corrosion Resistance: Our aluminum cylinders are manufactured using advanced techniques that enhance their corrosion resistance. This ensures a longer lifespan and consistent performance even in challenging environments.

- High Strength-to-Weight Ratio: The remarkable strength-to-weight ratio of aluminum makes our gas cylinders capable of containing gases at high pressures while remaining manageable for users.

- Non-Reactive Properties: Aluminum is non-reactive with a wide range of gases, making it a safe choice for storing and transporting various life-sustaining gases without the risk of contamination or chemical reactions.

- Eco-Friendly Choice: Aluminum is highly recyclable, aligning with sustainable practices. Choosing aluminum gas cylinders contributes to reducing the environmental impact while maintaining safety standards.

Applications in Life Support

- Medical Oxygen Supply: Our aluminum gas cylinders play a critical role in providing medical oxygen to patients in hospitals, clinics, and emergency medical services. Their reliability and purity ensure a consistent oxygen supply for those in need.

- Search and Rescue Operations: In disaster-stricken areas or hazardous environments, reliable life support equipment is essential. Aluminum gas cylinders support search and rescue operations by providing necessary gases for breathing apparatuses and other life-sustaining devices.

- Diving Industry: For underwater exploration and commercial diving, the dependability of life support equipment is paramount. Aluminum gas cylinders supply breathing gases for divers, ensuring their safety and wellbeing during deep-sea operations.

Trusted Supplier and Manufacturer

As a reputable company in the industry, we take pride in our commitment to quality and safety. Our aluminum gas cylinders undergo rigorous testing and adhere to international standards, guaranteeing their suitability for critical life support applications. Our experienced team of professionals ensures that each cylinder is manufactured with precision and care, reflecting our dedication to providing top-tier products to our customers.

Conclusion

In the realm of life support systems, the importance of reliable equipment cannot be overstated. Our company, as a prominent supplier and manufacturer of aluminum gas cylinders, stands ready to provide you with the ultimate solution for your life support needs. With their lightweight design, corrosion resistance, and exceptional performance, our aluminum gas cylinders ensure the safety and well-being of individuals in various critical situations. Choose our trusted products to make a difference when it matters the most.

Aluminum gas Cylinders Size

DOT 3AL Aluminum Gas Cylinder

| NO. | Outside Diameter | Service Pressure | Test pressure | Water Volume | Certified | Standard | Certification Body | ||||||

| Liters | lbs | ||||||||||||

| mm | in | bar | psi | bar | psi | min | max | min | max | ||||

| 1 | 50 | 1.97 | 250 | 3625 | 417 | 6042 | 0.26 | 0.46 | 0.57 | 1.01 | DOT | DOT 3AL | DOT |

| 2 | 60 | 2.36 | 166 | 2408 | 250 | 3626 | 0.35 | 0.65 | 0.77 | 1.43 | DOT | UN ISO7866 | DOT |

| 3 | 61 | 2.40 | 207 | 3000 | 345 | 5000 | 0.4 | 0.7 | 0.88 | 1.54 | DOT | DOT 3AL | DOT |

| 4 | 73.8 | 2.91 | 160 | 2321 | 200 | 2901 | 0.62 | 0.62 | 1.36 | 1.36 | DOT | DOT 39 | DOT |

| 5 | 73.8 | 2.91 | 120 | 1740 | 180 | 2611 | 0.2 | 1.5 | 0.44 | 3.31 | DOT | UN ISO11118 | DOT |

| 6 | 73.8 | 2.91 | 150 | 2176 | 225 | 3263 | 0.2 | 1.5 | 0.44 | 3.31 | DOT | UN ISO11118 | DOT |

| 7 | 81.5 | 3.21 | 153 | 2216 | 255 | 3694 | 0.6 | 1.3 | 1.32 | 2.87 | DOT | DOT 3AL | DOT |

| 8 | 81.5 | 3.21 | 124 | 1800 | 207 | 3000 | 0.63 | 1.17 | 1.39 | 2.58 | DOT | DOT 3AL | DOT |

| 9 | 90 | 3.54 | 207 | 3000 | 345 | 5000 | 0.92 | 1.68 | 2.03 | 3.70 | DOT | DOT 3AL | DOT |

| 10 | 111.3 | 4.38 | 139 | 2015 | 232 | 3359 | 1.2 | 2 | 2.65 | 4.41 | DOT | DOT 3AL | DOT |

| 11 | 111.3 | 4.38 | 124 | 1800 | 207 | 3000 | 0.98 | 1.82 | 2.16 | 4.01 | DOT | DOT 3AL | DOT |

| 12 | 111.3 | 4.38 | 139 | 2015 | 232 | 3359 | 2.52 | 4.68 | 5.56 | 10.32 | DOT | DOT 3AL | DOT |

| 13 | 133.4 | 5.25 | 153 | 2216 | 255 | 3694 | 3.9 | 7 | 8.60 | 15.43 | DOT | DOT 3AL | DOT |

| 14 | 133.4 | 5.25 | 124 | 1800 | 207 | 3000 | 2.38 | 4.42 | 5.25 | 9.74 | DOT | DOT 3AL | DOT |

TPED EN ISO7866 Aluminum Gas Cylinder

| NO. | Outside Diameter | Service Pressure | Test pressure | Water Volume | Certified | Standard | Certification Body | ||||||

| Liters | lbs | ||||||||||||

| mm | in | bar | psi | bar | psi | min | max | min | max | ||||

| 1 | 60 | 2.36 | 166 | 2408 | 250 | 3626 | 0.4 | 0.67 | 0.88 | 1.48 | TPED | EN ISO7866 | TUV |

| 2 | 60.5 | 2.38 | 200 | 2901 | 300 | 4351 | 0.35 | 0.7 | 0.77 | 1.54 | TPED | EN ISO7866 | TUV |

| 3 | 80 | 3.15 | 32 | 464 | 48 | 696 | 0.6 | 1.5 | 1.32 | 3.31 | TPED | EN ISO7866 | TI |

| 4 | 70 | 2.76 | 120 | 1740 | 180 | 2611 | 0.2 | 1.2 | 0.44 | 2.65 | TPED | EN ISO11118 | TUV |

| 5 | 73.8 | 2.91 | 120 | 1740 | 180 | 2611 | 0.2 | 1.3 | 0.44 | 2.87 | TPED | EN ISO11118 | TUV |

| 6 | 81.5 | 3.21 | 124 | 1798 | 186 | 2698 | 0.6 | 1.5 | 1.32 | 3.31 | TPED | EN ISO7866 | TUV |

| 7 | 90 | 3.54 | 200 | 2901 | 300 | 4351 | 0.7 | 1.6 | 1.54 | 3.53 | TPED | EN ISO7866 | TUV |

| 8 | 90 | 3.54 | 166 | 2408 | 250 | 3626 | 0.7 | 1.6 | 1.54 | 3.53 | TPED | EN ISO7866 | TUV |

| 9 | 111 | 4.37 | 124 | 1798 | 186 | 2698 | 1.4 | 3.9 | 3.09 | 8.60 | TPED | EN ISO7866 | TUV |

| 10 | 111 | 4.37 | 200 | 2901 | 300 | 4351 | 1.4 | 4 | 3.09 | 8.82 | TPED | EN ISO7866 | TUV |

| 11 | 120 | 4.72 | 166 | 2408 | 250 | 3626 | 1.4 | 4.5 | 3.09 | 9.92 | TPED | EN ISO7866 | TUV |

| 12 | 140 | 5.51 | 166 | 2408 | 250 | 3626 | 4 | 8 | 8.82 | 17.64 | TPED | EN ISO7866 | TUV |

| 13 | 140 | 5.51 | 200 | 2901 | 300 | 4351 | 3 | 9 | 6.61 | 19.84 | TPED | EN ISO7866 | TUV |

| 14 | 184 | 7.24 | 166 | 2408 | 250 | 3626 | 6 | 15 | 13.23 | 33.07 | TPED | EN ISO7866 | TUV |

| 15 | 184 | 7.24 | 200 | 2901 | 300 | 4351 | 6 | 16 | 13.23 | 35.27 | TPED | EN ISO7866 | TUV |

| 16 | 203 | 7.99 | 166 | 2408 | 250 | 3626 | 11 | 20 | 24.25 | 44.09 | TPED | EN ISO7866 | TUV |

GB/T 11640 Aluminum Gas Cylinder

| NO. | Outside Diameter | Service Pressure | Test pressure | Water Volume | Certified | Standard | Certification Body | ||||||

| Liters | lbs | ||||||||||||

| mm | in | bar | psi | bar | psi | min | max | min | max | ||||

| 1 | 60 | 2.36 | 150 | 2176 | 225 | 3263 | 0.2 | 0.6 | 0.44 | 1.32 | TS | GB/T 11640 | TS |

| 2 | 60 | 2.36 | 300 | 4351 | 450 | 6527 | 0.2 | 0.5 | 0.44 | 1.10 | TS | GB/T 11640 | TS |

| 3 | 81.5 | 3.21 | 150 | 2176 | 225 | 3263 | 0.7 | 1.5 | 1.54 | 3.31 | TS | GB/T 11640 | TS |

| 4 | 111.3 | 4.38 | 200 | 2901 | 300 | 4351 | 1.1 | 4 | 2.43 | 8.82 | TS | GB/T 11640 | TS |

| 5 | 140 | 5.51 | 150 | 2176 | 225 | 3263 | 3 | 9 | 6.61 | 19.84 | TS | GB/T 11640 | TS |

| 6 | 140 | 5.51 | 200 | 2901 | 300 | 4351 | 3 | 9 | 6.61 | 19.84 | TS | GB/T 11640 | TS |

| 7 | 184 | 7.24 | 200 | 2901 | 300 | 4351 | 6 | 15 | 13.23 | 33.07 | TS | GB/T 11640 | TS |

| 8 | 203 | 7.99 | 150 | 2176 | 225 | 3263 | 8 | 20 | 17.64 | 44.09 | TS | GB/T 11640 | TS |