Aluminum Oxygen Cylinders

- Standard: DOT, TPED, GB/T

- Material: aluminum alloy 6061-T6

- Applications: Medical Oxygen

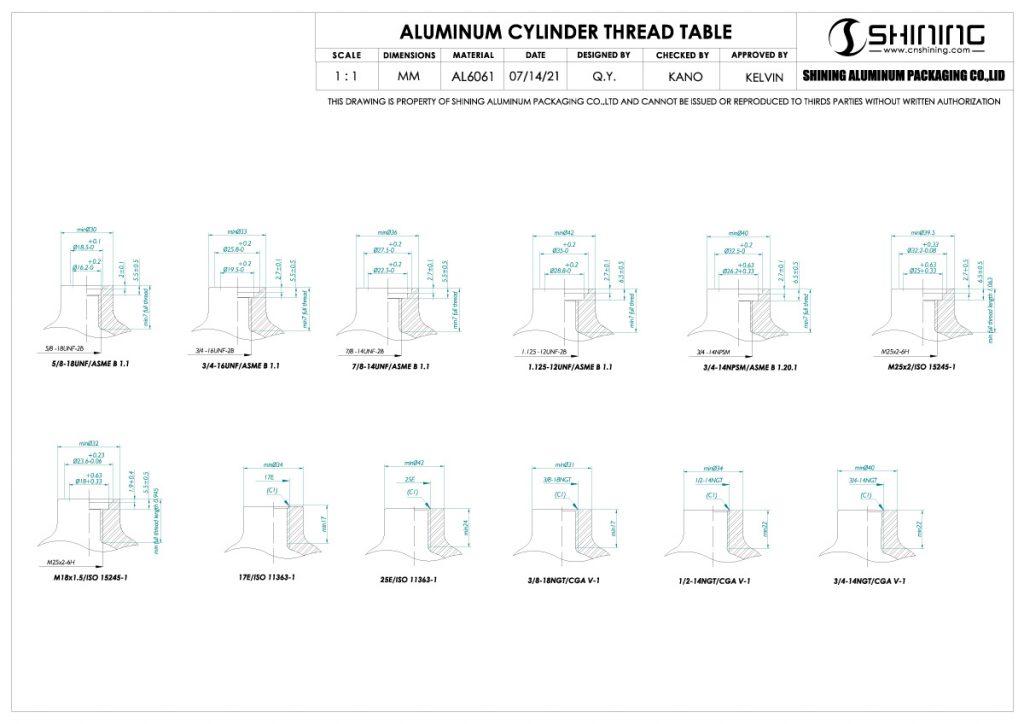

- Valve & Thread: Specified & Installed Upon Request

- Size: Custom Size is available with the TPED/DOT Certified Range

- Finish: Unpainted & Brushed & Different Color Coated

- Cleaning: Food Grade Cleaning by Ultrasonic Cleaners

- Delivery time: Usually 30-40 days Upon Quantity

From homes to healthcare settings, our stable, corrosion-resistant aluminum medical cylinders meet the needs of patients and the industry alike. We manufacture high-capacity cylinders for healthcare institutions in need of large quantities of medical gases and more compact, lightweight cylinders ideal for easy handling in homes and emergency situations.

- Material: We utilize a spectrum analyzer to ensure the stability of the material for aluminium oxygen cylinders, which are composed of aluminium alloy 6061-T6.

- Surface Finish: We offer a range of customization possibilities for the surface finish of aluminium cylinders. These options include polishing, body painting, and more.

- Food-Grade Cleaning: Utilizing ultrasonic cleaners, a process of food-grade cleaning is employed. The interior and exterior of the cylinders undergo meticulous purification with pristine water at a temperature of 70 degrees Celsius.

- Automatic Production: Utilizing automatic shaping machinery ensures the seamless refinement of cylinder interfaces, consequently elevating their safety quotient.

- Size Customizing: We welcome orders for customized sizes, as long as they fall within our certified range. Kindly furnish us with the specifications to enable us to assess and offer technical illustrations accordingly.

In the realm of modern medical care, precision and reliability are paramount. Medical professionals, caregivers, and patients alike rely on cutting-edge equipment to ensure the best possible outcomes. Enter the aluminum cylinder – a game-changer in the healthcare industry, particularly for the storage and transport of life-sustaining oxygen. In this article, we delve into the pivotal role of aluminum oxygen cylinders, shedding light on their benefits and introducing you to a trusted supplier and manufacturer that prioritizes quality and innovation.

Oxygen Cylinders: Lifelines in Healthcare

Oxygen, the elixir of life, is indispensable in medical settings. From emergency interventions to chronic respiratory conditions, having a dependable source of oxygen is critical. This is where aluminum oxygen cylinders step into the spotlight. Renowned for their lightweight yet robust nature, aluminum cylinders have revolutionized the way medical oxygen is stored, transported, and administered.

Unveiling a Range of Solutions

In the world of oxygen storage, terms like oxygen bottle, oxygen cartridge, oxygen tank, and oxygen canister are frequently used. These all refer to the vessels that hold life-sustaining oxygen in different capacities. Aluminum cylinders seamlessly accommodate these diverse forms, offering solutions tailored to specific medical requirements.

The Supplier You Can Trust

When it comes to medical equipment, trust is non-negotiable. As a leading supplier and manufacturer in the medical sector, our company is committed to delivering excellence. With years of experience and a dedication to innovation, we take pride in providing top-tier aluminum cylinders for medical use. Our products undergo rigorous quality checks, ensuring that each cylinder meets the highest standards of safety and performance.

Why Choose Aluminum Cylinders?

- Lightweight Durability: Aluminum cylinders combine the strength of traditional materials with a lightweight composition, making them easy to handle and transport without compromising on sturdiness.

- Corrosion Resistance: Medical environments demand equipment that can withstand moisture and other corrosive elements. Aluminum’s natural resistance to corrosion ensures the longevity of our cylinders, safeguarding the integrity of your oxygen supply.

- Enhanced Portability: Whether it’s a home care setting or a medical facility, the portability of aluminum cylinders ensures that life-saving oxygen is readily available where it’s needed most.

- Eco-Friendly Choice: Aluminum is not only durable but also environmentally friendly. It can be recycled repeatedly without losing its intrinsic properties, contributing to sustainable healthcare practices.

Beyond Quality: Our Commitment to You

As a company deeply rooted in the aluminum gas cylinder industry, we understand the significance of every oxygen cylinder we produce. Our commitment extends beyond manufacturing; we stand by you with comprehensive customer support and a dedication to meeting your unique needs.

Conclusion

In the ever-evolving landscape of medical care, the choice of equipment can make all the difference. Aluminum cylinders have emerged as a reliable, efficient, and safe means of storing and transporting medical oxygen. With our reputation as a trusted supplier and manufacturer, you can confidently embrace aluminum cylinders as an integral part of your medical arsenal. Experience the difference that quality, innovation, and dedication can bring – choose aluminum oxygen cylinders that put life first.

Aluminum gas Cylinders Size

DOT 3AL Aluminum Gas Cylinder

| NO. | Outside Diameter | Service Pressure | Test pressure | Water Volume | Certified | Standard | Certification Body | ||||||

| Liters | lbs | ||||||||||||

| mm | in | bar | psi | bar | psi | min | max | min | max | ||||

| 1 | 50 | 1.97 | 250 | 3625 | 417 | 6042 | 0.26 | 0.46 | 0.57 | 1.01 | DOT | DOT 3AL | DOT |

| 2 | 60 | 2.36 | 166 | 2408 | 250 | 3626 | 0.35 | 0.65 | 0.77 | 1.43 | DOT | UN ISO7866 | DOT |

| 3 | 61 | 2.40 | 207 | 3000 | 345 | 5000 | 0.4 | 0.7 | 0.88 | 1.54 | DOT | DOT 3AL | DOT |

| 4 | 73.8 | 2.91 | 160 | 2321 | 200 | 2901 | 0.62 | 0.62 | 1.36 | 1.36 | DOT | DOT 39 | DOT |

| 5 | 73.8 | 2.91 | 120 | 1740 | 180 | 2611 | 0.2 | 1.5 | 0.44 | 3.31 | DOT | UN ISO11118 | DOT |

| 6 | 73.8 | 2.91 | 150 | 2176 | 225 | 3263 | 0.2 | 1.5 | 0.44 | 3.31 | DOT | UN ISO11118 | DOT |

| 7 | 81.5 | 3.21 | 153 | 2216 | 255 | 3694 | 0.6 | 1.3 | 1.32 | 2.87 | DOT | DOT 3AL | DOT |

| 8 | 81.5 | 3.21 | 124 | 1800 | 207 | 3000 | 0.63 | 1.17 | 1.39 | 2.58 | DOT | DOT 3AL | DOT |

| 9 | 90 | 3.54 | 207 | 3000 | 345 | 5000 | 0.92 | 1.68 | 2.03 | 3.70 | DOT | DOT 3AL | DOT |

| 10 | 111.3 | 4.38 | 139 | 2015 | 232 | 3359 | 1.2 | 2 | 2.65 | 4.41 | DOT | DOT 3AL | DOT |

| 11 | 111.3 | 4.38 | 124 | 1800 | 207 | 3000 | 0.98 | 1.82 | 2.16 | 4.01 | DOT | DOT 3AL | DOT |

| 12 | 111.3 | 4.38 | 139 | 2015 | 232 | 3359 | 2.52 | 4.68 | 5.56 | 10.32 | DOT | DOT 3AL | DOT |

| 13 | 133.4 | 5.25 | 153 | 2216 | 255 | 3694 | 3.9 | 7 | 8.60 | 15.43 | DOT | DOT 3AL | DOT |

| 14 | 133.4 | 5.25 | 124 | 1800 | 207 | 3000 | 2.38 | 4.42 | 5.25 | 9.74 | DOT | DOT 3AL | DOT |

TPED EN ISO7866 Aluminum Gas Cylinder

| NO. | Outside Diameter | Service Pressure | Test pressure | Water Volume | Certified | Standard | Certification Body | ||||||

| Liters | lbs | ||||||||||||

| mm | in | bar | psi | bar | psi | min | max | min | max | ||||

| 1 | 60 | 2.36 | 166 | 2408 | 250 | 3626 | 0.4 | 0.67 | 0.88 | 1.48 | TPED | EN ISO7866 | TUV |

| 2 | 60.5 | 2.38 | 200 | 2901 | 300 | 4351 | 0.35 | 0.7 | 0.77 | 1.54 | TPED | EN ISO7866 | TUV |

| 3 | 80 | 3.15 | 32 | 464 | 48 | 696 | 0.6 | 1.5 | 1.32 | 3.31 | TPED | EN ISO7866 | TI |

| 4 | 70 | 2.76 | 120 | 1740 | 180 | 2611 | 0.2 | 1.2 | 0.44 | 2.65 | TPED | EN ISO11118 | TUV |

| 5 | 73.8 | 2.91 | 120 | 1740 | 180 | 2611 | 0.2 | 1.3 | 0.44 | 2.87 | TPED | EN ISO11118 | TUV |

| 6 | 81.5 | 3.21 | 124 | 1798 | 186 | 2698 | 0.6 | 1.5 | 1.32 | 3.31 | TPED | EN ISO7866 | TUV |

| 7 | 90 | 3.54 | 200 | 2901 | 300 | 4351 | 0.7 | 1.6 | 1.54 | 3.53 | TPED | EN ISO7866 | TUV |

| 8 | 90 | 3.54 | 166 | 2408 | 250 | 3626 | 0.7 | 1.6 | 1.54 | 3.53 | TPED | EN ISO7866 | TUV |

| 9 | 111 | 4.37 | 124 | 1798 | 186 | 2698 | 1.4 | 3.9 | 3.09 | 8.60 | TPED | EN ISO7866 | TUV |

| 10 | 111 | 4.37 | 200 | 2901 | 300 | 4351 | 1.4 | 4 | 3.09 | 8.82 | TPED | EN ISO7866 | TUV |

| 11 | 120 | 4.72 | 166 | 2408 | 250 | 3626 | 1.4 | 4.5 | 3.09 | 9.92 | TPED | EN ISO7866 | TUV |

| 12 | 140 | 5.51 | 166 | 2408 | 250 | 3626 | 4 | 8 | 8.82 | 17.64 | TPED | EN ISO7866 | TUV |

| 13 | 140 | 5.51 | 200 | 2901 | 300 | 4351 | 3 | 9 | 6.61 | 19.84 | TPED | EN ISO7866 | TUV |

| 14 | 184 | 7.24 | 166 | 2408 | 250 | 3626 | 6 | 15 | 13.23 | 33.07 | TPED | EN ISO7866 | TUV |

| 15 | 184 | 7.24 | 200 | 2901 | 300 | 4351 | 6 | 16 | 13.23 | 35.27 | TPED | EN ISO7866 | TUV |

| 16 | 203 | 7.99 | 166 | 2408 | 250 | 3626 | 11 | 20 | 24.25 | 44.09 | TPED | EN ISO7866 | TUV |

GB/T 11640 Aluminum Gas Cylinder

| NO. | Outside Diameter | Service Pressure | Test pressure | Water Volume | Certified | Standard | Certification Body | ||||||

| Liters | lbs | ||||||||||||

| mm | in | bar | psi | bar | psi | min | max | min | max | ||||

| 1 | 60 | 2.36 | 150 | 2176 | 225 | 3263 | 0.2 | 0.6 | 0.44 | 1.32 | TS | GB/T 11640 | TS |

| 2 | 60 | 2.36 | 300 | 4351 | 450 | 6527 | 0.2 | 0.5 | 0.44 | 1.10 | TS | GB/T 11640 | TS |

| 3 | 81.5 | 3.21 | 150 | 2176 | 225 | 3263 | 0.7 | 1.5 | 1.54 | 3.31 | TS | GB/T 11640 | TS |

| 4 | 111.3 | 4.38 | 200 | 2901 | 300 | 4351 | 1.1 | 4 | 2.43 | 8.82 | TS | GB/T 11640 | TS |

| 5 | 140 | 5.51 | 150 | 2176 | 225 | 3263 | 3 | 9 | 6.61 | 19.84 | TS | GB/T 11640 | TS |

| 6 | 140 | 5.51 | 200 | 2901 | 300 | 4351 | 3 | 9 | 6.61 | 19.84 | TS | GB/T 11640 | TS |

| 7 | 184 | 7.24 | 200 | 2901 | 300 | 4351 | 6 | 15 | 13.23 | 33.07 | TS | GB/T 11640 | TS |

| 8 | 203 | 7.99 | 150 | 2176 | 225 | 3263 | 8 | 20 | 17.64 | 44.09 | TS | GB/T 11640 | TS |