Hersteller von Beuteln mit Ventil

Bei Shining Aluminum Packaging sind wir herausragend im Design, der Entwicklung, Produktion und Lieferung von Aerosoldosen und Spenderverpackungslösungen. Unser umfangreiches Produktsortiment umfasst Aerosoldosen, Ventile, Aktuatoren, BOV-Systeme und verschiedenes Zubehör. Wir erfüllen sowohl die technischen als auch die ästhetischen Bedürfnisse unserer Kunden und ermöglichen ihnen, sich abzuheben und auf einem wettbewerbsintensiven Markt erfolgreich zu sein.

- 30 - 500 ml

- Automatische Produktionslinie

- FDA und LFGB

- 24-Stunden-BOV-Lecktest

- GMP-Workshop

- 300.000 Stück/Tag

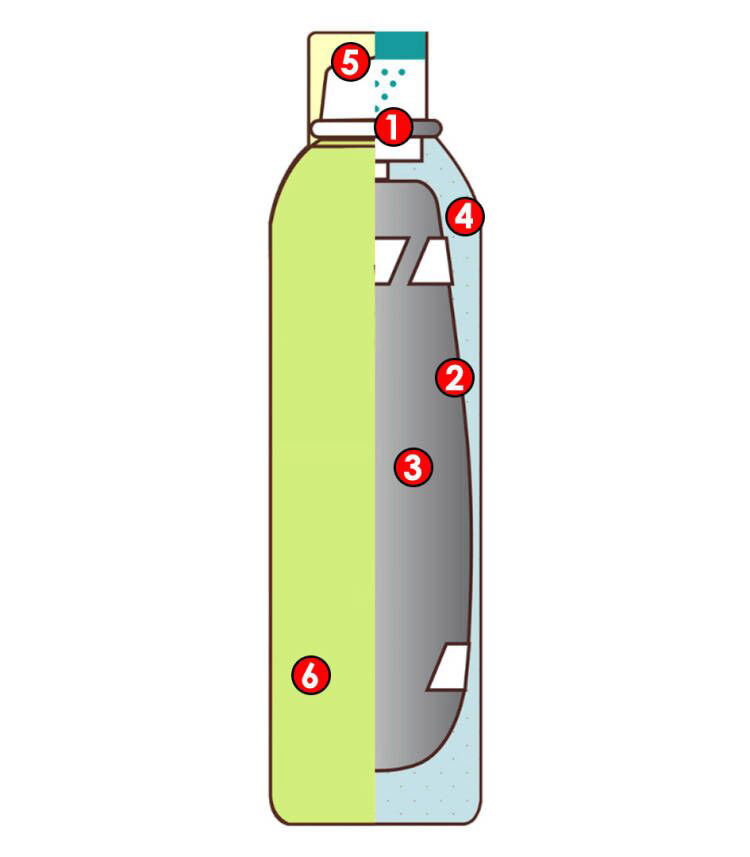

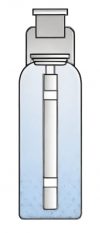

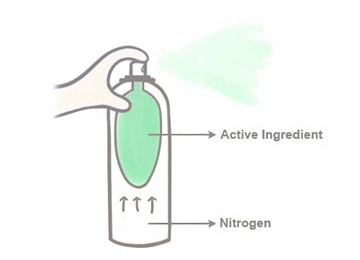

Bag-On-Valve-Technologie

- 1. Ventil: Bag-on-Valve (BOV)-Systeme sind sowohl mit weiblichen als auch mit männlichen Ventilen erhältlich.

- 2. BOV: Diese Systeme verfügen über FDA- und LFGB-zugelassene, mehrschichtige laminierte Beutel, die in vielen Größen von 1 fl. oz. bis 14 fl. oz. erhältlich sind.

- 3. Produkt: BOV-Systeme eignen sich für Flüssigkeiten und die meisten viskosen Produkte wie Cremes und Lotionen in zahlreichen Anwendungsbereichen. Sie sind für sauerstoffempfindliche und sterile Produkte optimiert. Beachten Sie, dass Trockenpulver nicht mit BOV-Systemen kompatibel sind.

- 4. Treibmittel: Es sollten Luft oder Stickstoff verwendet werden, niemals flüssige Gase.

- 5. Aktuator und Kappe: Je nach Produktanforderungen ist eine große Auswahl an Standard-Betätigern verfügbar. Einige Betätigungselemente, wie z. B. der Drehverschluss-Betätiger, benötigen keine Kappe. Standard-Überkappen können mit vielen Arten von Behältern und Betätigungselementen verwendet werden.

- 6. Aerosoldose: Es können standardmäßige DOT-Druckbehälter aus Aluminium, Stahl und Weißblech verwendet werden. Eine Vielzahl unterschiedlich geformter Behälter ist kompatibel.

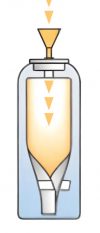

Bag-On-Valve-Aerosol-Abfüllprozess

SCHRITT 1

Platzierung des BOV im Container

SCHRITT 2

Dem Behälter wird Druck zugeführt

SCHRITT 3

Crimpen und Versiegeln des Behälters Zum Behälter

SCHRITT 4

Produktfüllung im Behälter Durch das Ventil

SCHRITT 5

Führen Sie einen Wasserbadtest durch, um sicherzustellen, dass keine Leckagen vorliegen

SCHRITT 6

Aktuator- und Kappenplatzierung

Bag On Valve Aerosoldosengröße

| Produktnummer | Größe der Spraydose (mm) | BOV-Füllmenge (ml) | BOV-Größe (mm) |

| NV25.4E-30 | Φ35×90 | 30 | 60x65x25 |

| NV25.4E-50 | Φ35×110 | 50 | 90x65x25 |

| NV25.4E-80 | Φ40×120 | 80 | 100x80x25 |

| NV25.4E-100 | Φ45×125 | 100 | 100x90x25 |

| NV25.4E-150 | Φ45×150 | 125 | 125x90x25 |

| NV25.4E-150 | Φ50×150 | 150 | 125x90x25 |

| NV25.4E-200 | Φ53×180 | 200 | 145x100x32 |

| NV25.4E-300 | Φ53×215 | 300 | 180x100x32 |

| NV25.4E-300-2 | Φ66×180 | 300 | 150x115x35 |

| NV25.4E-400 | Φ66×215 | 400 | 190x115x35 |

| NV25.4E-500 | Φ66×240 | 500 | 213x115x35 |

Beutel auf Ventilspraydose

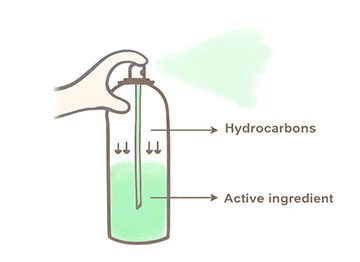

Beutel mit Ventil vs. Aerosol

| Sprühdose | Beutel am Ventil | |

|---|---|---|

|  | |

| Dichtheit | Schlechte Versiegelung, kein Beutel zum Schutz der Körperverpackung | Mehrere Schutzmaterialkörper durch Ventile gebildet, vierlagige Vakuumbeutel |

| Produkt rein | Die Treibmittel und Zutaten sind vermischt, die Zutat ist nicht rein genug | Die Treibmittel und Inhaltsstoffe sind getrennt, keine Verträglichkeitsprobleme |

| Zerstäubung | Schlechte Zerstäubung | Kontinuierliche Nanozerstäubung |

| Bequemlichkeit | Sediment haben, vor Gebrauch schütteln und während des Gebrauchs mehrmals drücken | Kein Sediment, jederzeit sprühen, kein mehrfaches Drücken erforderlich |

| Winkel verwenden | Kann nicht auf den Kopf gestellt werden | 360° |

| Nutzung | Rückstände haben, Abfall | >98% |

| Jet-Sound | Zischen | Stumm |

| Umwelt und Sicherheit | Das Treibmittel wird aus dem Tank abgegeben, brennbar | Das Treibmittel wird nicht aus der Dose abgegeben, belastet die Umwelt nicht und verringert die Entflammbarkeit des Produkts |

| Treibmittel | Kohlenwasserstoffe | Stickstoff, Luft |

| Preis | Billig | Teuer |

| Füllen | Zuerst die Zutaten, dann die Treibmittel | Treibmittel zuerst, dann Inhaltsstoff |

BOV-Aerosol-Aktuatoren

Markt für Bag-On-Ventil-Technologie

Verschiedenes

Feuerlöscher, Lufterfrischer, Geruchsneutralisierer, Autopflegeprodukte, Insektenschutzmittel, Desinfektionsmittel

Kosmetika

Sonnenschutz, Lotionen, Cremes, Gesichtswaschmittel, Selbstbräunungsspray, Körperhygiene

Essen

Speiseöle, flüssige Aromen, Essige, Salatdressings, flüssiger Tee und Kaffee

Pharmazeutika und OTC

OTC-Produkte, Wundspülungen, Nasensprays, Ohrenspülungen, Augenspülungen, Erste-Hilfe-Sprays, Babypflege

Veterinär & Haustier

Wundspülungen für Pferde, Anti-Pilz-Spray, Floh- und Zeckenspray, Haarpolitur und -entwirrer, Lederreiniger und -spülung