Como fabricante de válvulas para aerosoles, comprender los intrincados mecanismos que se esconden detrás de estos componentes es esencial para crear productos eficaces y fiables. Las válvulas para aerosoles pueden parecer sencillas, pero requieren una ingeniería precisa para garantizar un flujo de producto constante, control de la presión y un sellado seguro. Profundicemos en el funcionamiento de las válvulas para aerosoles, destacando los mecanismos clave, las funciones básicas y las adaptaciones específicas para cada aplicación.

Mecánica de las válvulas de aerosol

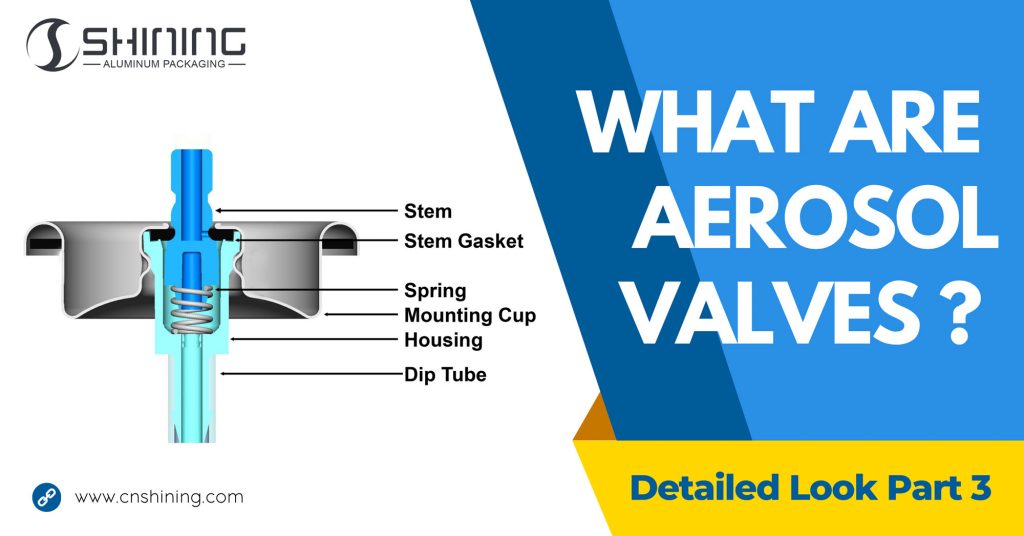

El mecanismo de una válvula de aerosol involucra varios componentes clave que trabajan juntos para proporcionar una pulverización controlada. A continuación, se muestra cómo contribuye cada parte:

- Solenoide:Esta es la parte que los usuarios presionan para liberar el aerosol. Controla el flujo y el patrón del producto al dirigirlo a través de orificios específicos de la boquilla. Un actuador bien diseñado es crucial para garantizar una aplicación uniforme y uniforme.

- Vástago y junta del vástago:El vástago se conecta al actuador y es el encargado de gestionar el flujo del producto. La junta, una pequeña pieza de goma, actúa como interruptor de encendido y apagado sellando los orificios cuando no se utiliza.

- Primavera y Vivienda:El resorte mantiene la válvula cerrada cuando no se presiona el actuador, lo que ayuda a mantener la frescura del producto. La carcasa encierra estas piezas y ayuda a regular la salida del rociador.

- Tubo de inmersión y copa de montaje:El tubo de inmersión extrae el producto del recipiente, mientras que la copa de montaje une la válvula con el recipiente, formando un sello hermético. Es posible que los distintos productos requieran variaciones en la longitud y el diámetro del tubo de inmersión.

Funciones básicas

Las válvulas de aerosol cumplen tres funciones principales: dispensando, caza de focas, y contención del propulsorA continuación se muestra cómo funciona cada una de estas funciones dentro del sistema:

1. Dispensación

La función principal de la válvula de aerosol es dispensar el producto de manera controlada. Cuando se presiona el actuador, la válvula se abre, lo que permite que el producto presurizado fluya como un rocío fino, espuma o niebla, según la fórmula y el diseño del actuador. Esta acción permite precisión y minimiza el desperdicio de producto, lo que hace que los aerosoles sean convenientes y eficientes.

2. Sellado

La capacidad de sellado de la válvula es esencial para preservar el contenido y garantizar la seguridad del usuario. La junta del vástago y el resorte trabajan juntos para mantener la válvula sellada cuando no está en uso, lo que evita fugas y contaminación. Un sello de alta calidad es especialmente crítico para productos sensibles a la exposición al aire o propensos a la evaporación.

3. Contención del propulsor

Es fundamental contener el propulsor presurizado de forma segura dentro del envase. Las válvulas de aerosol están diseñadas para soportar la presión interna generada por propulsores como gases licuados o aire comprimido. Para ciertas aplicaciones, el uso de un sistema de barrera o de bolsa en envase puede proteger aún más el producto y mantener una presión estable durante la vida útil del aerosol.

Adaptaciones entre aplicaciones

Las válvulas para aerosoles están diseñadas para satisfacer las necesidades específicas de diferentes industrias, desde la farmacéutica hasta la cosmética y más allá. Veamos algunos ejemplos:

1. Aplicaciones farmacéuticas

En los aerosoles médicos, como los inhaladores, es fundamental controlar la dosis con precisión. Se utilizan válvulas dosificadoras especiales para dispensar una cantidad constante y medida de medicamento con cada pulverización. Estas válvulas suelen utilizar materiales y mecanismos especializados para garantizar la seguridad y la precisión del paciente.

2. Cosméticos y cuidado personal

En productos de cuidado personal como desodorantes y lacas para el cabello, el diseño de la válvula se centra en lograr una pulverización fina y uniforme. Los actuadores con insertos MBU (mecánicamente disgregables) son comunes, lo que crea un patrón de pulverización óptimo para una cobertura uniforme.

3. Productos industriales y domésticos

En el caso de productos como lubricantes y agentes de limpieza, la durabilidad y la resistencia a diversos productos químicos son fundamentales. Las válvulas para estas aplicaciones están diseñadas con materiales resistentes para soportar contenidos potencialmente corrosivos y garantizar un patrón de rociado duradero.

Consejos profesionales y perspectivas del sector

- Elija el propulsor adecuado:La selección de un propulsor adecuado es esencial para el rendimiento del producto. Por ejemplo, los gases comprimidos como el nitrógeno ofrecen una presión constante a lo largo del tiempo, ideal para productos que requieren un flujo constante.

- Utilice actuadores MBU para una niebla fina:Los actuadores de ruptura mecánica mejoran la finura de la pulverización, lo que resulta especialmente beneficioso para aplicaciones cosméticas.

- Mantener la integridad del sello:Pruebe periódicamente la junta del vástago y el resorte para evitar posibles fugas, especialmente si su producto es sensible a la exposición al aire.

- Considere la personalización de la válvula:Se pueden diseñar válvulas personalizadas para adaptarse a requisitos específicos, incluida la velocidad de pulverización, el tamaño de partícula y la fuerza de actuación, según el producto.

Preguntas frecuentes sobre la mecánica de las válvulas de aerosol

- ¿Cómo controla una válvula de aerosol el patrón de pulverización? El patrón de pulverización está controlado principalmente por el diseño del actuador y la boquilla, que dirige el flujo y dispersa el producto en consecuencia.

- ¿Qué materiales se utilizan en las válvulas de aerosol? Los materiales comunes incluyen acero inoxidable para resortes, plástico para actuadores y caucho para juntas, cada uno elegido por su durabilidad y compatibilidad con el producto.

- ¿Por qué se obstruyen algunas válvulas de aerosol? Las obstrucciones pueden deberse a fórmulas con alto contenido de sólidos o a un almacenamiento inadecuado. El mantenimiento y las pruebas regulares pueden ayudar a prevenir problemas de obstrucciones.

- ¿Qué es un actuador MBU? MBU, o Mechanical Break-Up, es un tipo de actuador diseñado para crear una niebla más fina y consistente al canalizar el producto a través de cámaras de remolino.

- ¿Cómo funcionan los sistemas de barrera con válvulas de aerosol? Los sistemas de barrera separan el producto del propulsor mediante una bolsa o pistón, ideal para formulaciones sensibles o productos espumosos.

- ¿Cómo puedo evitar que mi válvula de aerosol tenga fugas? Asegúrese de que el conjunto de la válvula tenga un sellado hermético, especialmente en la copa de montaje y la junta del vástago, y evite la exposición a temperaturas extremas.

- ¿Cuál es la diferencia entre válvulas verticales y de inclinación? Las válvulas verticales se abren cuando se presionan hacia abajo, mientras que las válvulas inclinables se abren cuando se empujan hacia un lado, lo que ofrece versatilidad para diferentes ángulos de pulverización.

- ¿Puedo utilizar cualquier actuador con cualquier válvula? No siempre; los actuadores deben coincidir con el diseño de la válvula para lograr compatibilidad y un control adecuado de la pulverización.

- ¿Cómo selecciono la válvula de aerosol adecuada para mi producto? Tenga en cuenta factores como la viscosidad del producto, los requisitos del patrón de pulverización y la compatibilidad del propulsor.

- ¿Por qué es importante el engarce en el ensamblaje de la válvula de aerosol? El engarce asegura la válvula a la lata y garantiza un sellado hermético, crucial para la seguridad y la integridad del producto.

¿Está listo para obtener más información o solicitar válvulas de aerosol personalizadas? Visite nuestra página de productos en https://www.cnshining.com/aerosol-valve-manufacturer ¡Explora nuestra gama o contáctanos directamente para obtener soluciones personalizadas!