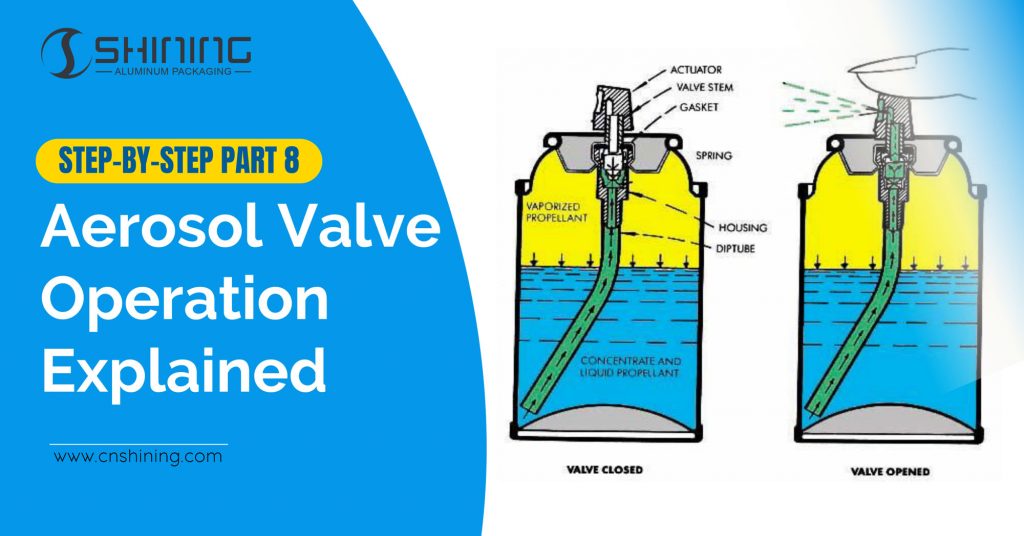

Introducción al funcionamiento de las válvulas de aerosol

Al considerar la entrega eficaz de productos en aerosol, uno de los componentes esenciales que lo hacen posible es el válvula de aerosolEstos mecanismos, sencillos pero críticos, son fundamentales para garantizar que el contenido se distribuya de forma segura y uniforme desde las latas de aerosol, y cubren una amplia gama de productos, desde artículos de cuidado personal hasta aplicaciones industriales. fabricantes y proveedores de válvulas de aerosol, entendemos la precisión y la experiencia necesarias para fabricar estos componentes para una funcionalidad y un rendimiento óptimos.

Hoy, analizaremos en profundidad el proceso paso a paso de las operaciones de las válvulas de aerosol, y le brindaremos información que puede mejorar su comprensión y confianza a la hora de seleccionar la válvula de aerosol adecuada para sus necesidades. Desde la presión inicial del actuador hasta la gestión del flujo del producto y el mantenimiento de patrones de pulverización constantes, lo guiaremos a través de cada aspecto de la mecánica de las válvulas de aerosol. Además, compartiremos algunos consejos de expertos y datos menos conocidos sobre la funcionalidad de las válvulas que pueden resultarle útiles.

Cómo funcionan las válvulas de aerosol: desde la presión del actuador hasta la liberación del producto

Las válvulas de aerosol funcionan a través de una secuencia coordinada que comienza con el actuador. El actuador es la parte de la válvula que el usuario presiona o inclina para liberar el producto dentro de la lata. A medida que se aplica presión al actuador, este presiona el vástago de la válvula, rompiendo el sello dentro de la carcasa de la válvula y permitiendo que el propulsor empuje el producto hacia afuera.

La fuerza inicial aplicada al actuador inicia este proceso, pero hay más que tener en cuenta además de la simple presión. El material del actuador, su diseño y la fuerza necesaria para presionarlo influyen en la forma en que se dispensa el producto. Históricamente, las válvulas de aerosol se desarrollaron para agilizar el proceso de dispensación en aplicaciones donde la precisión es fundamental. Hoy en día, los actuadores están diseñados para varios estilos de pulverización, ya sea una niebla fina o un chorro dirigido, lo que mejora el control del usuario sobre la experiencia de dispensación.

Un consejo útil: la elección del tipo de actuador adecuado puede afectar drásticamente al rendimiento del producto. En sectores como el de la cosmética, los actuadores con una pulverización más fina garantizan aplicaciones más uniformes, mientras que los productos industriales suelen beneficiarse de un actuador más resistente capaz de manipular soluciones más espesas.

Gestión del flujo de productos: el papel de los tubos de inmersión y la carcasa

El tubo de inmersión y la carcasa de la válvula son fundamentales para controlar el flujo del producto dentro de una lata de aerosol. El tubo de inmersión se extiende desde la válvula hacia abajo dentro del producto, lo que permite que el contenido se extraiga y se libere cuando se activa el actuador. El diseño y la longitud del tubo de inmersión se calibran cuidadosamente en función de la viscosidad y la densidad del producto, así como de la salida de pulverización deseada.

Por ejemplo, en los aerosoles de grado alimenticio, el tubo de inmersión está diseñado para garantizar una contaminación mínima y mantener los estándares de seguridad alimentaria. Además, la carcasa de la válvula (donde se encuentran el vástago, el resorte y las juntas) sirve como cámara de control, lo que garantiza que el flujo del producto sea constante y controlado, lo que evita ráfagas repentinas o patrones de pulverización irregulares.

¿Sabías que? La longitud del tubo de inmersión también puede influir en la cantidad de producto que se utiliza dentro de una lata, lo que ayuda a reducir el desperdicio al maximizar la dispensación del producto. Por ejemplo, un tubo de inmersión bien diseñado puede alcanzar incluso las últimas gotas en el fondo, lo que garantiza un uso eficiente del producto.

Cómo mantener patrones de pulverización constantes: técnicas para un rendimiento confiable

La uniformidad en los patrones de pulverización es fundamental, especialmente en el caso de productos en aerosol que requieren una aplicación uniforme, como pinturas, revestimientos o desodorantes. Para lograr un rendimiento de pulverización uniforme es necesario diseñar con precisión cada componente de la válvula, incluido el actuador, el vástago y el tubo de inmersión, así como el tipo de propulsor.

Un actuador de ruptura mecánica (MBU), por ejemplo, contiene una cámara de remolino dentro de su diseño, lo que le permite producir una niebla fina y uniforme al dirigir el producto hacia canales controlados antes de que salga. Esta tecnología, conocida como ruptura mecánica, es particularmente beneficioso para aplicaciones donde es esencial una pulverización precisa y uniforme.

Históricamente, el desarrollo de patrones de rociado consistentes surgió de requisitos industriales, donde la pulverización irregular podía generar un rendimiento deficiente del producto. Hoy en día, mantener un patrón de rociado consistente es una expectativa en muchos productos de consumo. Los fabricantes confían en procesos de prueba, como el análisis del patrón de rociado, para garantizar que cada válvula funcione como se espera.

Consejo profesional: al seleccionar una válvula de aerosol, tenga en cuenta el patrón de rociado necesario para su aplicación. Para los productos de cuidado personal, puede ser preferible una niebla más suave y fina, mientras que los productos industriales pueden necesitar una pulverización más densa para una mayor cobertura.

Preguntas frecuentes: comprensión del funcionamiento de las válvulas de aerosol

- ¿Cuál es el propósito de un actuador en una válvula de aerosol? El actuador controla la liberación del producto presionando el vástago de la válvula, lo que permite dispensar el producto.

- ¿Cómo afecta el tubo de inmersión al flujo del producto? El tubo de inmersión aspira el producto desde el fondo de la lata hasta la válvula, lo que influye en la cantidad de producto que se puede dispensar de manera efectiva.

- ¿Cuál es el papel del propulsor en las válvulas de aerosol? El propulsor crea la presión necesaria para empujar el producto a través de la válvula, lo que permite patrones de pulverización suaves y consistentes.

- ¿Se puede personalizar la longitud del tubo de inmersión? Sí, la longitud se puede ajustar para adaptarse a formulaciones de productos específicos y maximizar el uso del producto dentro de la lata.

- ¿Qué tipos de actuadores están disponibles para diferentes patrones de pulverización? Los actuadores pueden variar desde actuadores de niebla fina hasta actuadores de pulverización más potentes, dependiendo del propósito del producto.

- ¿Cómo funciona un actuador MBU? Un actuador MBU utiliza una cámara de remolino para dividir el producto en una fina niebla, ideal para una aplicación uniforme.

- ¿Por qué es importante el engarzado en el montaje de válvulas? El engarce asegura la válvula a la lata, garantizando que no haya fugas y manteniendo una presión constante.

- ¿Cuáles son algunos problemas comunes con las válvulas de aerosol? Las fugas, las obstrucciones y los patrones de rociado irregulares son problemas comunes, a menudo debidos a un ensamblaje inadecuado o a desajustes de componentes.

- ¿Cómo puedo asegurarme de que mi válvula de aerosol proporcione un patrón de pulverización uniforme? Los controles de calidad regulares, incluido el análisis del patrón de pulverización, pueden ayudar a mantener la consistencia en el rendimiento.

- ¿Existen opciones sostenibles para los propelentes de aerosol? Sí, hay propelentes ecológicos disponibles que reducen el impacto ambiental.

Para obtener más información y especificaciones detalladas sobre los productos de válvulas de aerosol, visite nuestra página de productos en https://www.cnshining.com/aerosol-valve-manufacturer o contáctenos para conocer cómo nuestro equipo puede respaldar sus necesidades de válvulas de aerosol.