Shining Aluminium Packaging は、中国における高圧ガスボンベの大手サプライヤーです。当社は 2001 年以来、ボンベの研究開発に力を注いでおり、飲料、スキューバ、医療、防火、特殊産業向けに優れた品質の製品を提供することを目指しています。

アルミガスシリンダーメーカー

装置

当社の品質管理は、ISO、DOT、TPED などの国際基準に厳密に準拠することで保証されており、顧客の要件と期待、および国際基準を満たすかそれを超えるために、ISO9001 に準拠した高度な自動機械と生産システムを備えています。

お客様の声

貴社のサービスと印刷およびアルミニウム製品の品質の高さに心から感謝しており、アルミニウム包装を含む新しいプロジェクトにおける参考サプライヤーとして貴社を考慮しています。

ワファハルーム プロジェクトオフィサー

あなたは私たちの素晴らしいパートナーであり、この最も異常な時期にさらなる柔軟性が必要であることを理解していただければ幸いです。

クリス・トウCOO

前の

次

探している アルミガスシリンダー?

アルミガスシリンダーの究極ガイド

1. はじめに

1.1 アルミガスシリンダーの定義

アルミニウム ガス シリンダーは、酸素、窒素、ヘリウム、二酸化炭素などの圧縮ガスを保管および輸送するために設計された 6061 アルミニウム製の容器です。これらのシリンダーは通常、持ち運び可能な軽量の圧縮ガス源が必要なさまざまな産業および医療用途で使用されます。

アルミ製ガスボンベはスチール製ボンベに比べて、軽量で持ち運びやすく、耐腐食性に優れているため寿命が延びるなど、いくつかの利点があります。さらに、アルミ製ボンベは熱伝導率が高いため、ガスの充填および排出時に効率的に熱を放散できます。ただし、アルミ製ボンベは製造に使用される材料のコストが高いため、スチール製ボンベよりも高価になる場合があります。

1.2 アルミガスシリンダーの歴史

アルミニウム製ガスボンベの歴史は、アルミニウムが高圧容器の製造に適した材料であることが初めて発見された 20 世紀初頭にまで遡ります。アルミニウムが使用される前は、ガスボンベは通常、重くて錆びやすい鋼鉄または鉄で作られていました。

1920 年代、ドイツのマンネスマン社は、新興の航空業界向けにアルミニウム製ガスシリンダーの生産を開始しました。これらのシリンダーは当初、航空機の空気圧システムで圧縮空気を貯蔵するために使用されていました。スチール製のシリンダーよりも軽量であったため、重量が重要な要素となる航空機での使用に最適でした。

アルミニウム製ガスボンベは、1940 年代から 1950 年代にかけて、溶接、ダイビング、医療用酸素貯蔵など、さまざまな用途で広く使用されるようになりました。これらのボンベは通常、軽量で強度の高い容器を生み出すシームレスな押し出し加工を使用して製造されました。

アルミニウム ガス シリンダーの設計は、時とともに進化し、材料、製造プロセス、安全基準が改善されてきました。今日、アルミニウム ガス シリンダーは、医療、産業、レジャーなどのさまざまな分野で使用されています。軽量、耐久性、耐腐食性が高く評価されており、多くの現代技術において重要なコンポーネントとなっています。

1.3 アルミガスシリンダーの利点

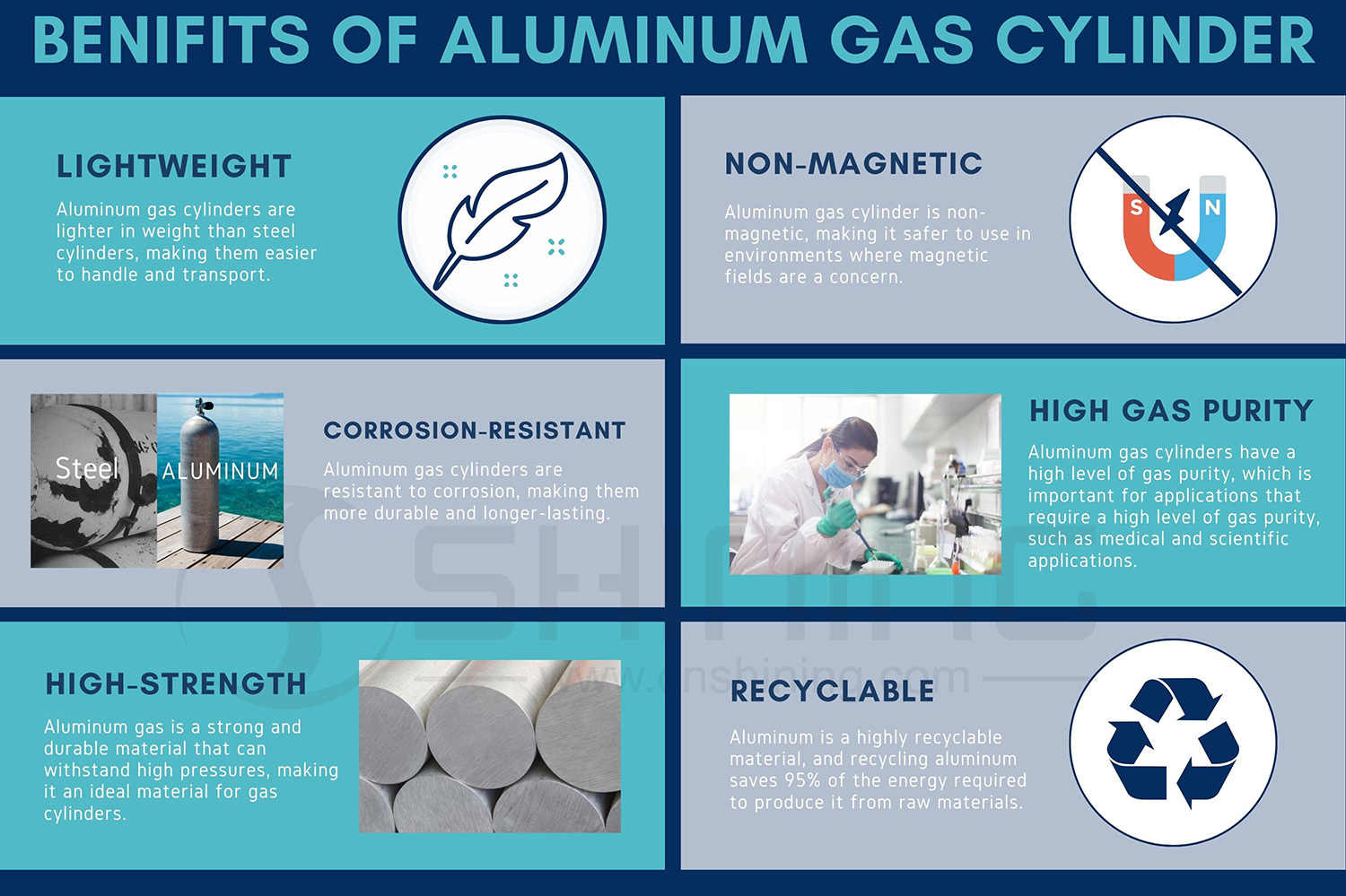

アルミニウム製ガスシリンダーを使用すると、次のようないくつかの利点があります。

- 軽量: アルミニウム製ガスシリンダーはスチール製シリンダーよりも軽量なので、取り扱いや輸送が簡単です。

- 耐腐食性: アルミニウム製ガスシリンダーは耐腐食性があり、耐久性が高く、長持ちします。

- 高強度: アルミニウムガスは高圧に耐えられる強度と耐久性に優れた素材で、ガスシリンダーに最適です。

- 非磁性: アルミニウムガスシリンダーは非磁性であるため、磁場が懸念される環境でも安全に使用できます。

- 高いガス純度: アルミニウム製ガスボンベはガス純度が高く、医療や科学用途など、高いガス純度が求められる用途には不可欠です。

- リサイクル可能: アルミニウムはリサイクル性の高い素材であり、アルミニウムをリサイクルすると、原材料からアルミニウムを製造するために必要なエネルギーの 95% を節約できます。つまり、アルミニウム製ガスシリンダーは繰り返しリサイクルできるため、廃棄物が減り、天然資源が保護されます。

2. アルミガスシリンダー構造

アルミニウム製ガスボンベは、通常、軽量で耐久性のある構造を提供する高強度アルミニウム合金で作られています。ボンベの具体的な設計は、使用目的によって異なりますが、ほとんどのアルミニウム製ガスボンベは、同様の基本構造になっています。

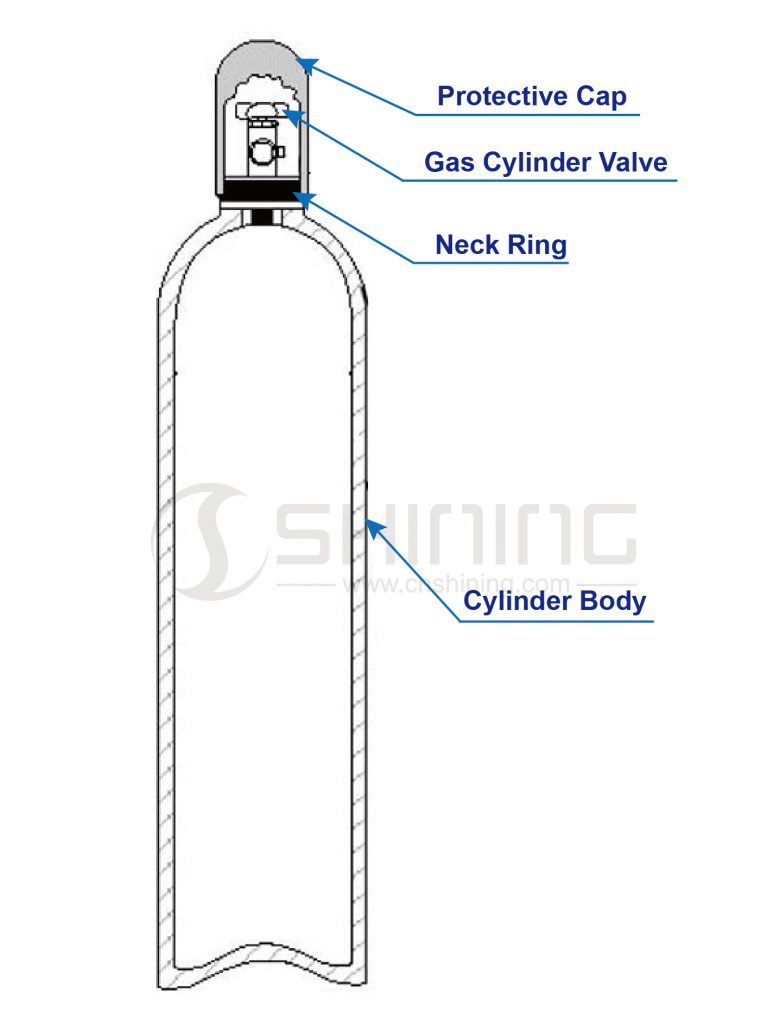

アルミニウムガスシリンダーの主な構成部品は次のとおりです。

シリンダー本体: これはシリンダーの主要部分であり、通常は円筒形です。本体は、高圧に耐えられるように設計されたシームレスな押し出しアルミニウム合金管で作られています。シリンダーの圧力定格によって、シリンダー壁の厚さが決まります。

ネックリング: これはシリンダー本体の上部にあるカラーです。ネック リングはバルブの安全な取り付けポイントを提供し、取り扱い中や輸送中にシリンダーを損傷から保護します。ネック リングは通常、ねじではなくリベットで固定されます。ねじを使用するとアルミニウム ガス シリンダーの壁厚が薄くなるためです。

ガスボンベバルブ: ガスボンベバルブは、ガスボンベに出入りするガスの流れを制御する装置です。通常は真鍮または鋼で作られており、耐久性があり高圧に耐えられるように設計されています。バルブは通常、ねじ接続を使用してアルミニウムシリンダーに接続され、バルブホイールまたはハンドルを使用して開閉できます。ガスボンベバルブは安全で信頼性が高くなるように設計されており、通常はいくつかの安全機能が組み込まれています。たとえば、多くのバルブには、シリンダー内の圧力が一定レベルを超えると自動的にガスを排出する圧力解放装置が付いています。これにより、シリンダーが爆発したり破裂したりするのを防ぐことができます。

保護キャップ: 保護キャップは、シリンダーが使用されていないときにバルブを損傷や汚染から保護するためにバルブの上に取り付けられるプラスチックまたは金属製のカバーです。

全体的に、アルミニウム製ガスシリンダーの設計は、高圧ガスを安全に収容できる、強固で軽量、かつ耐久性のある構造を提供することに重点を置いています。シリンダーの具体的なコンポーネントと機能は、使用目的とアプリケーションの要件によって異なります。

3. アルミガスシリンダーのマーキング

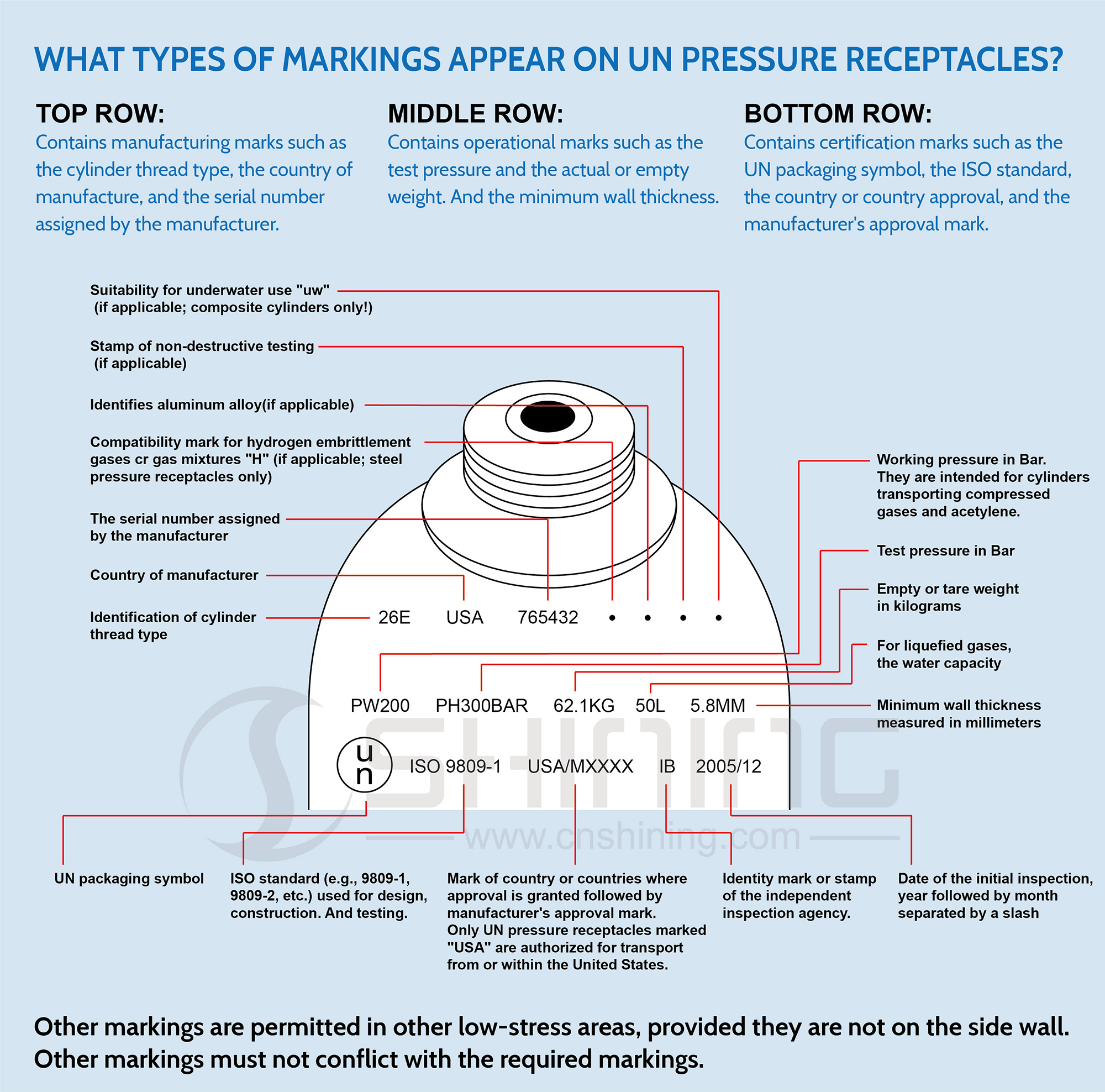

アルミニウム製ガスシリンダーには、運輸省 (DOT) およびカナダ運輸省 (TC) が定める規制に従ってマークを付ける必要があります。マークには、シリンダーの内容物、使用方法、安全性に関する重要な情報が記載されています。

アルミニウム製ガスシリンダーに表示される標準的なマークは次のとおりです。

上段: シリンダーのねじの種類、製造国、メーカーが割り当てたシリアル番号などの製造マークが含まれます。

- 該当する場合は水中での使用「uw」に適合します。複合シリンダーのみ。

- 非破壊検査のスタンプ(該当する場合)

- アルミニウム合金を識別します (該当する場合)。

- 水素脆化ガスまたはガス混合物の適合性マーク「H」(該当する場合、鋼製圧力容器のみ)

- 製造元によって割り当てられたシリアル番号

- 製造国

- シリンダーねじタイプの識別

中段: 試験圧力、実重量または空重量、および最小壁厚などの動作マークが含まれます。

- 作動圧力はバール単位です。圧縮ガスやアセチレンを輸送するシリンダーに使用されます。

- 試験圧力(バール)

- 空重量または風袋重量(キログラム)

- 液化ガスの場合、水の容量

- 最小壁厚(ミリメートル単位)

下段: UN 包装シンボル、ISO 規格、国または国の承認、製造元の承認マークなどの認証マークが含まれます。

- 国連包装シンボル

- 設計、構築、テストに使用される ISO 規格 (例: 9809-1、9809-2 など)。

- 承認が付与された国または地域のマークの後に製造元の承認マークが続きます。「USA」マークの付いた UN 圧力容器のみが米国からの輸送または米国内での輸送が許可されています。

- 独立検査機関の識別マークまたはスタンプ。

- 初回検査の日付、年と月をスラッシュで区切って表記

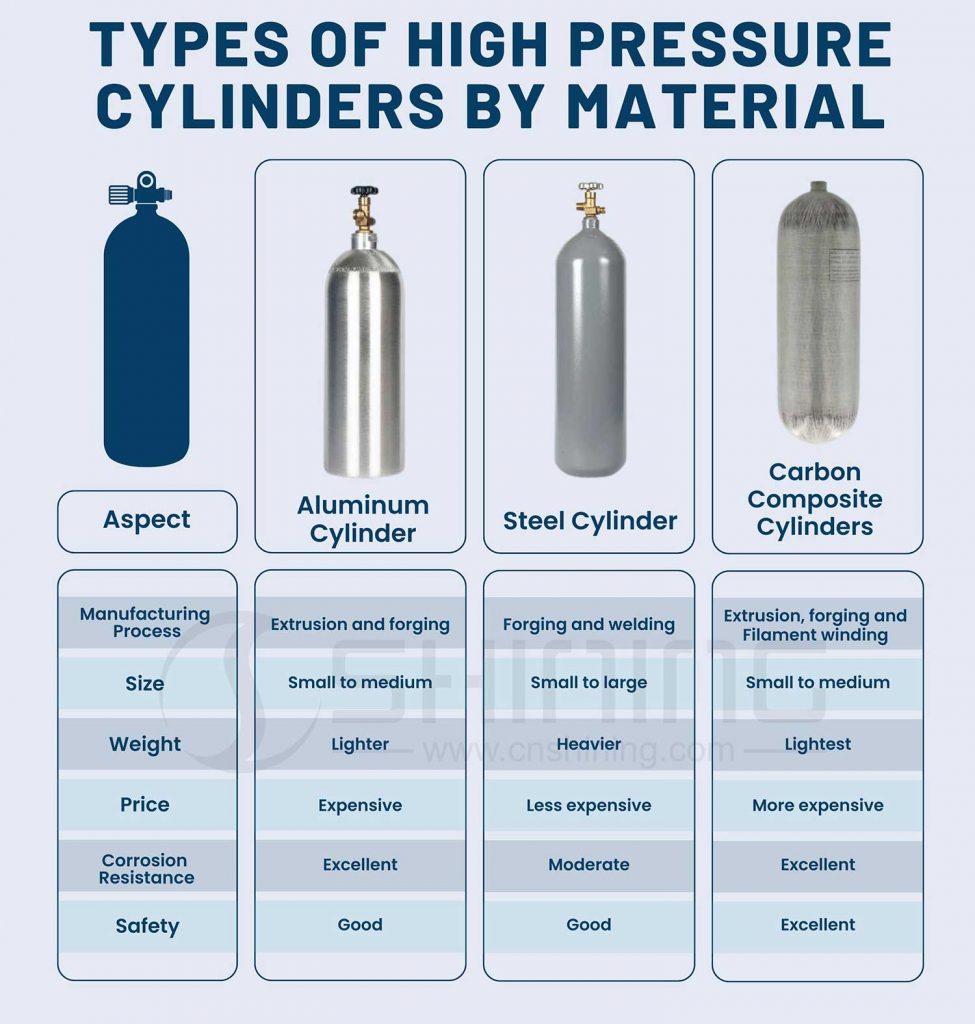

4. 材質別高圧シリンダーの種類

スチールシリンダー、アルミニウムシリンダー、複合シリンダーは、さまざまなガスを貯蔵および輸送するために使用されるさまざまな高圧シリンダーです。

スチールシリンダー 最も一般的なタイプのガスボンベで、通常は継ぎ目のない引抜炭素鋼で作られています。耐久性があり、高圧に耐えられるため、さまざまなガスの保管や輸送に適しています。また、スチールボンベは比較的安価で、何度も再利用できます。ただし、重量があり、適切にメンテナンスしないと腐食しやすくなります。

アルミシリンダー は、スチールシリンダーのより軽量な代替品です。高強度アルミニウム合金で作られており、スチールシリンダーよりも耐腐食性に優れています。アルミニウムシリンダーはスチールシリンダーよりも高価ですが、軽量で耐腐食性があるため、スキューバダイビングや医療用酸素などの特定の用途で人気があります。

カーボンファイバー複合シリンダー 薄肉アルミ合金製内筒を採用し、炭素繊維複合材を巻いています。スチール製やアルミ製のシリンダーよりも軽量で、強度と耐久性に優れます。複合シリンダーは耐腐食性にも優れ、酸素、窒素、二酸化炭素など幅広いガスを貯蔵できます。ただし、スチール製やアルミ製のシリンダーよりも高価です。

要約すると、各タイプのシリンダーにはそれぞれ独自の長所と短所があり、どのタイプを使用するかの選択はアプリケーションの特定の要件によって異なります。

5. アルミガスシリンダーの色

アルミニウム製ガスボンベは、用途や業界に応じてさまざまな色があります。アルミニウム製ガスボンベの最も一般的な色は、金属の自然な色である銀色です。ただし、製造業者は、識別や安全上の目的で、ペイントや粉体塗装を使用してボンベにさまざまな色を塗ることもあります。

ガスボンベの色分けは、安全な取り扱い、保管、輸送を確保するために、業界標準に従って標準化されることがよくあります。たとえば、米国では、圧縮ガス協会 (CGA) がガスボンベの肩マークとバルブ保護キャップの色分けシステムを確立しました。このシステムでは、特定の色を使用して、ガスの種類、危険レベル、その他の重要な情報を示します。

- 銀: アルミニウム製ガスボンベの最も一般的な色は、金属の自然な色である銀色です。これらのボンベはさまざまなガスに使用できますが、通常は特定のガスの種類用に指定されていません。

- 緑: 緑色のシリンダーは酸素ガスによく使用されます。酸素は植物の生命にとって不可欠であり、緑色は自然と成長に関連付けられているからです。

- 茶色: 茶色のボンベは、通常、溶接や切断の用途でよく使用されるアセチレン ガスに使用されます。この色は、他の可燃性ガスにも使用されることがあります。

- グレー: 灰色のシリンダーは炭酸ガスによく使用され、炭酸ソーダやビールなど、食品や飲料の用途でよく使用されます。

- 青: 青いボンベは亜酸化窒素によく使用されます。この色は、他の不燃性ガスにも使用されることがあります。

- 赤: 赤いボンベは、消火器によく使用されます。消火器には、消火に使用される圧縮ガスが入っています。この色は、他の種類の圧縮ガスにも使用されることがあります。

ボンベの色はメーカーによって異なる場合があり、ガスを識別するために使用される色分けシステムは地域や国によって異なる場合があることに注意することが重要です。したがって、ガスボンベを正しく識別するには、ボンベのラベルを確認するか、訓練を受けた専門家に相談することが常に重要です。

6. アルミガスシリンダーバルブ接続継手アダプタタイプ

CGA (Compressed Gas Association) と DIN (Deutsches Institut für Normung) は、ガスシリンダー継手の 2 つの規格です。

アメリカ標準: CGA

CGA 継手は北米で一般的に使用されており、番号システム (例: CGA 320、CGA 580) で識別されます。これらの継手には、適切なガス シリンダー バルブに接続できるように設計された特定の寸法とねじがあります。標準的な CGA 継手には次のものがあります。

- CGA 320: 二酸化炭素やその他の不活性ガスに使用

- CGA 580: 圧縮空気と窒素に使用

- CGA 540:酸素用

- CGA 870: 医療用酸素に使用される

- CGA 510: アセチレン用

- CGA 590: アルゴン用

- CGA 180: ヘリウム用

- CGA 200:窒素用

- CGA 326: 亜酸化窒素に使用

欧州規格: DIN 477

DIN 継手はヨーロッパで一般的に使用されており、DIN 番号 (例: DIN 477-1、DIN 477-5) で識別されます。これらの継手には、適切なガス シリンダー バルブに接続できるように設計された特定の寸法とねじ山もあります。標準的な DIN 継手には次のものがあります。

- DIN 477-1: 窒素およびアルゴンに使用

- DIN 477-5: 二酸化炭素に使用

- DIN 477-6: 酸素用

- DIN 477-7: プロパンとブタンに使用

- DIN 477-8: 水素に使用

- DIN 477-9: ヘリウム用

- DIN 477-10: アセチレン用

CGA フィッティング付きのガス シリンダーを DIN フィッティングが必要なシステムに接続する必要がある場合 (またはその逆)、フィッティング アダプターを使用できます。DIN アダプターはさまざまな CGA フィッティングに使用でき、CGA アダプターはさまざまな DIN フィッティングに使用できます。

英国規格: BS341

ガス シリンダー バルブ接続に関する英国標準規格 BS341 では、ガス シリンダーで使用されるさまざまな種類のバルブ接続が定義されています。BS341 で指定されているさまざまなタイプの接続は次のとおりです。

- BS 341 No. 2 – この接続はブタンガスとプロパンガスに使用され、21.7mm バルブとも呼ばれます。

- BS 341 No. 3 – この接続は液化石油ガス (LPG) に使用され、25mm バルブとも呼ばれます。

- BS 341 No. 4 – この接続はアセチレン ガスに使用され、9/16 インチ バルブとも呼ばれます。

- BS 341 No. 6 – この接続は酸素ガスに使用され、3/4 インチ バルブとも呼ばれます。

- BS 341 No. 8 – この接続は二酸化炭素ガスに使用され、5/8 インチ バルブとも呼ばれます。

- BS 341 No. 10 – この接続は窒素ガスに使用され、1 1/8 インチ バルブとも呼ばれます。

- BS 341 No. 13 – この接続はアルゴンガスに使用され、5/8 インチ バルブとも呼ばれます。

シリンダーバルブの出口と接続

BS、CGA、DIN 標準の出口接続を備えたバルブ付きガス シリンダー。場合によっては、代替接続が使用されることがあり、顧客の要求に応じて、以下に示す標準の代わりに提供されます。

| ガス | BS | CGA | ディン | ガス | BS | CGA | ディン |

| アセチレン | 2 | 510 | – | 塩化水素 | 6 | 330 | 8 |

| 空気 | 3 | 590 | 6 | 硫化水素 | 15 | 330 | 5 |

| アレン | – | 510 | 1 | イソブタン | 4 | 510 | 1 |

| アンモニア、無水 | 10 | 240, 660 | 8 | イソブチレン | 4 | 510 | 1 |

| アルゴン | 3 | 580 | 10 | クリプトン | 3 | 580 | 10 |

| アルシン | 4 | 350 | 5 | メタン | 4 | 350 | 1 |

| 1,3-ブタジエン | 4 | 510 | 1 | 塩化メチル | 7 | 660 | 5 |

| ブタン | 4 | 510 | 1 | メチルメルカプタン | – | 330 | 5 |

| ブテン | 4 | 510 | 1 | モノエチルアミン | 11 | 240 | 5 |

| 二酸化炭素 | 8 | 320 | 6 | モノメチルアミン | 11 | 240 | 5 |

| 一酸化炭素 | 4 | 350 | 5 | 天然ガス | 4 | 350 | 1 |

| フッ化カルボニル | – | 660 | 8 | ネオン | 3 | 580 | 10 |

| 硫化カルボニル | – | 330 | 5 | 一酸化窒素 | 14 | 660 | 8 |

| 塩素 | 6 | 660 | 8 | 窒素 | 3 | 580 | 10 |

| シアン | – | 660 | 8 | 二酸化窒素 | 14 | 660 | 8 |

| 重水素 | 4 | 350 | 1 | 亜酸化窒素 | 13 | 326 | 6 |

| ジメチルアミン | 11 | 240 | 5 | 酸素 | 3 | 540 | – |

| ジメチルエーテル | – | 510 | 1 | ホスゲン | 6 | 660 | 8 |

| エタン | 4 | 350 | 1 | ホスフィン | 4 | 350 | 5 |

| エチルアセチレン | – | 510 | 1 | プロパン | 4 | 510 | 1 |

| エチルクロリド | 7 | 510 | 1 | プロピレン | 4 | 510 | 1 |

| エチレン | 4 | 350 | 1 | シラン | – | 350 | 5 |

| エチレンオキシド | 7 | 510 | 1 | 四フッ化ケイ素 | – | 330 | 8 |

| ハロカーボン14 | 6 | 580 | 6 | 二酸化硫黄 | 12 | 660 | 8 |

| ハロカーボン22 | 6 | 660 | 6 | 六フッ化硫黄 | 6 | 590 | 6 |

| ヘリウム | 3 | 580 | 10 | トリメチルアミン | 11 | 240 | 5 |

| 水素 | 4 | 350 | 1 | 塩化ビニル | 7 | 510 | 5 |

| 臭化水素 | – | 330 | 8 | キセノン | 3 | 580 | 10 |

| 塩化水素 | 6 | 330 | 8 |

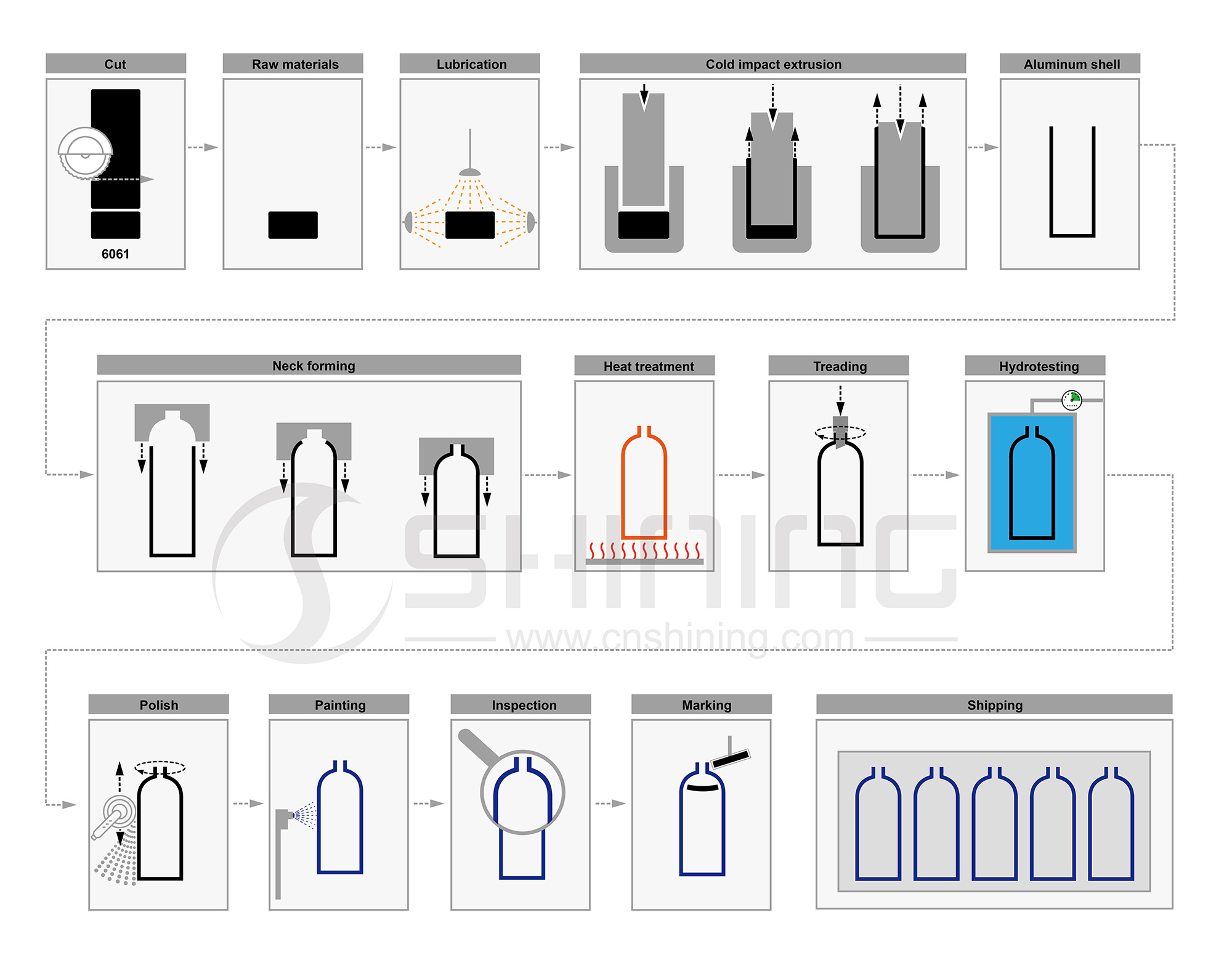

7. アルミガスシリンダーの製造

アルミニウム製ガスシリンダーの製造プロセスに含まれる手順の概要は次のとおりです。

原材料: アルミニウムガスシリンダーの製造に使用される主な原材料は、6061 合金から作られたアルミニウムスラグです。スラグは円筒形の金属片で、最終的にシリンダーの本体を形成します。

潤滑: 製造工程中の摩擦を減らすためにスラグに潤滑剤を塗布します。これにより、押し出し中にスラグがダイに付着するのを防ぐことができます。

冷間衝撃押し出し: 次に、潤滑されたスラグを金型に入れて冷間衝撃押し出し加工します。この加工では、スラグを高圧で圧縮して円筒形のシェルを形成します。

ネック形成: シェルが形成された後、上端が成形され、バルブが取り付けられるネックが形成されます。

熱処理: 次に、シェルは熱処理を受け、強度と硬度を高めるために焼き入れが行われます。その後、シェルは T6 溶体化処理炉で熟成され、必要な強度と耐久性が得られます。

踏みつけ: シェルの上端には、バルブを取り付けるためのねじ山が切られています。

水圧試験: 次に、シリンダーは水圧テストを受け、水で満たされて加圧され、必要な圧力に耐えられるかどうかが確認されます。

研磨: 次に、シリンダーを研磨して表面の欠陥を取り除き、滑らかな表面を作ります。

絵画: シリンダーには、腐食から保護し、見た目を美しくするために耐久性のあるコーティングが施されています。

検査: シリンダーは、必要なすべての仕様と基準を満たしていることを確認するために検査されます。

マーキング: シリンダーには、製造元の名前、シリアル番号、その他の識別マークなど、さまざまなコードが刻印されています。

配送: 最後に、シリンダーは梱包され、注文した顧客に発送されます。

これは製造工程の一般的な概要であり、具体的な詳細は製造元やシリンダーの用途によって異なる場合があります。

8. ガスシリンダーの試験と認証

アルミニウム ガス シリンダーのテストと認証は、各国の規制と基準により国によって異なります。以下は、さまざまな国におけるアルミニウム ガス シリンダーのテストと認証の例です。

アメリカ: 米国では、アルミニウム製ガスシリンダーは運輸省 (DOT) によって規制されています。シリンダーは、静水圧試験や超音波試験などの特定の方法を使用して、5 年ごとに DOT 認定施設でテストおよび認定を受ける必要があります。シリンダーには、DOT 仕様マーク、製造元の名前と住所、シリンダーのシリアル番号などの特定のマークも付いている必要があります。

カナダ: カナダでは、アルミニウム製ガスシリンダーはカナダ運輸省によって規制されています。シリンダーは、水圧試験や目視検査などの特定の試験方法を使用して、TC 認定施設で 10 年ごとに試験および認定を受ける必要があります。シリンダーには、TC 仕様マーク、製造元の名前と住所、シリンダーのシリアル番号などの特定のマークも付いている必要があります。

イギリス: 英国では、アルミニウム製ガスシリンダーは、健康安全局 (HSE) によって規制されています。シリンダーは、用途に応じて 5 年または 10 年ごとに、HSE 認定施設で、静水圧テストや目視検査などの特定のテスト方法を使用してテストおよび認定を受ける必要があります。シリンダーには、EN 仕様マーク、製造元の名前と住所、シリンダーのシリアル番号などの特定のマークも付いている必要があります。

欧州連合: 欧州連合では、アルミニウム製ガスシリンダーは圧力機器指令 (PED) および可搬型圧力機器指令 (TPED) に準拠する必要があります。これらの指令は、アルミニウム製シリンダーを含むガスシリンダーのテストと認証の枠組みを提供します。シリンダーは、静水圧テストや超音波テストなどの特定のテスト方法を使用して、認定機関によって 10 年ごとにテストされ、認証される必要があります。シリンダーには、CE マーク、製造元の名前と住所、シリンダーのシリアル番号などの特定のマークも付いている必要があります。

オーストラリア: オーストラリアでは、アルミニウム製ガスボンベはオーストラリアガス協会 (AGA) によって規制されています。ボンベは、静水圧試験や目視検査などの特定の試験方法を使用して、AGA 認定施設で 10 年ごとに試験および認定を受ける必要があります。また、ボンベには、AGA 仕様マーク、製造元の名前と住所、ボンベのシリアル番号などの特定のマークを付ける必要があります。

これらの規制や基準は時間の経過とともに変更される可能性があり、ガスボンベの種類や使用目的によっても異なる場合があることに留意することが重要です。したがって、アルミニウム製ガスボンベが自国の適切なテストおよび認証要件を満たしていることを確認するには、資格のある専門家または規制機関に相談することが常に最善です。

9. アルミガスシリンダーの用途

さまざまな用途に使用されるアルミニウムガスシリンダーにはいくつかの種類があります。

- SCBA(自給式呼吸装置)シリンダーこれらのアルミニウム製ガスボンベは、危険な環境で呼吸保護を必要とする消防士、救助隊員、産業労働者によって使用されます。

- 工業用および溶接用シリンダー: これらのアルミニウム製ガスシリンダーは、製造業、建設業、金属加工業などの業界で、溶接、切断、その他の工業プロセスに使用されます。

- 医療用シリンダー: これらのアルミニウム製ガスボンベは、医療現場で酸素、窒素、ヘリウムなどの医療用ガスを保管および輸送するために使用されます。

- 消火器シリンダー: これらのアルミニウム製ガスボンベは、二酸化炭素や窒素などの圧縮ガスを貯蔵するために消火器で使用されます。

- 飲料シリンダー: これらのアルミニウム製ガスシリンダーは、飲料業界で、ソフトドリンク、ビール、その他の飲料の炭酸化のために二酸化炭素を貯蔵および分配するために使用されます。

- 代替燃料シリンダー: これらのアルミニウム製ガスシリンダーは、車両の代替燃料として圧縮天然ガス (CNG) または液化石油ガス (LPG) を貯蔵します。

- 特殊ガスボンベ: これらのアルミニウム製ガスボンベは、研究、製造、その他の特殊な用途で使用される校正ガス、希ガス、高純度ガスなどの特殊ガスの保管および輸送に使用されます。

- インフレーションおよび航空宇宙用シリンダー: これらのアルミニウム製ガスシリンダーは、航空宇宙産業において、航空機の緊急用スライド、いかだ、救命胴衣を膨らませるために使用されます。

- パフォーマンスレーシングシリンダー: これらのアルミニウム製ガスシリンダーは、エンジンブースト用の亜酸化窒素を貯蔵および分配するために、パフォーマンスレースで使用されます。

- サンプリングシリンダー: これらのアルミニウム製ガスシリンダーは、環境モニタリング、ガス分析、および分析用のガスサンプルの保管と輸送などの科学的用途で使用されます。

- 亜酸化窒素ボンベ: 亜酸化窒素用アルミニウムガスボンベは、亜酸化窒素ガスの保管と輸送に使用されます。亜酸化窒素は無色で甘い香りのガスで、医療や歯科の現場では軽い麻酔薬や鎮痛剤としてよく使用されます。また、食品業界ではホイップクリームの推進剤として、自動車業界ではレーシングカーの性能向上添加剤として使用されています。

10. アルミガスボンベの安全上の注意

アルミニウム製ガスボンベを取り扱い、使用する際に守るべき重要な安全上の注意事項は次のとおりです。

10.1 適切な取り扱いと保管:

- シリンダーが倒れないように常に垂直に保ってください。

- シリンダーを移動するには適切な台車またはカートを使用し、床に引きずらないようにしてください。

- 使用していないときは、シリンダーが落下したり倒れたりしないように適切に固定してください。

- バルブやレギュレータを持ってシリンダーを持ち上げないでください。

10.2 定期的な点検とメンテナンス:

- シリンダーが良好な状態であることを確認するために、資格のある技術者に定期的に検査してもらってください。

- へこみ、ひび割れ、腐食などの損傷の兆候が見られる場合は、シリンダーを交換してください。

- バルブまたはレギュレータが損傷していたり、摩耗の兆候が見られる場合は交換してください。

10.3 極端な温度への暴露の回避:

- シリンダーを熱源、炎、火花から遠ざけてください。

- シリンダーを 130°F (54°C) を超える温度または -40°F (-40°C) を下回る温度にさらさないでください。

- シリンダーは直射日光を避け、涼しく乾燥した場所に保管してください。

これらの安全上の注意事項に従うことで、事故を防ぎ、アルミニウム製ガスボンベの安全な取り扱いと使用を確保することができます。

11. 中国アルミガスシリンダーメーカー

高品質のアルミニウム製ガスシリンダーが必要な場合は、Shining Aluminum Packaging などの中国の評判の良いメーカーに問い合わせることを検討してください。当社は、さまざまな用途に使用できる信頼性と耐久性に優れたアルミニウム製ガスシリンダーを製造してきた実績があります。

詳しい情報や見積もり依頼については、お気軽にお問い合わせください。専門知識と品質へのこだわりにより、お客様の特定のニーズに最適なソリューションをご提供いたします。

12. よくある質問

アルミニウムシリンダーは、酸素、窒素、二酸化炭素などの圧縮ガスを保管および輸送するために使用されます。工業、医療、研究室の現場でよく使用されます。

アルミシリンダーは厳しい安全基準を満たし、定期的に検査およびテストを受ける必要があります。シリンダーにテストおよび認定済みであることを示すマークがあるかどうかを確認し、有効期限をチェックして、まだ耐用年数内であることを確認してください。

アルミシリンダーは、熱、炎、発火源から離れた、涼しく乾燥した換気の良い場所に保管してください。倒れないように、垂直に立てて安定した位置に固定して保管してください。

はい、アルミニウムシリンダーは、適切にテストされ、認証されている限り、適切なガスまたはガス混合物で再充填できます。常に製造元の指示に従い、適切な充填装置を使用してください。

アルミニウムシリンダーは、輸送中に動いたり倒れたりしないように、安全な直立状態で固定して輸送する必要があります。また、換気の良い場所で輸送し、熱、炎、発火源から遠ざける必要があります。

はい、アルミシリンダーはリサイクルできます。アルミシリンダーを適切に処分する方法については、お近くのリサイクル施設に問い合わせてください。

アルミニウム シリンダーは、適切に取り扱わないと危険です。高熱や炎にさらされたり、破損したり、劣化したりすると爆発する可能性があります。アルミニウム シリンダーを取り扱う際は、常に適切な安全手順に従ってください。また、圧縮ガスにさらされたり、アルミニウム シリンダーが破損した場合は、直ちに医師の診察を受けてください。

ボンベバルブの圧力計は、そこに残っているガスの量を示します。ただし、圧力計はガスの圧力のみを示し、ボンベに残っているガスの量を示すわけではないことに注意することが重要です。したがって、残っているガスの量を正確に判断するには、ボンベの重量を測る必要がある場合があります。

アルミシリンダーは水中ダイビングに使用できますが、特別に設計され、認定されている必要があります。また、空気、ナイトロックス、トライミックスなど、ダイビングに適したガス混合物が充填されている必要があります。

アルミニウム シリンダーが破損または漏れている場合は、直ちに使用を中止し、認定シリンダー検査施設に持ち込んで検査と修理を受ける必要があります。破損したシリンダーを修理したり使用したりしないでください。

アルミニウム シリンダーは塗装またはコーティングできますが、シリンダー内に保管されているガスに適合する適切な塗料またはコーティングを使用することが重要です。推奨事項については、製造元または資格のあるシリンダー検査員にご相談ください。

アルミニウム シリンダーは、製造元および規制当局の指定に従って、定期的に検査およびテストする必要があります。これには通常、目視検査と静水圧テストが含まれ、シリンダーが圧力に安全に耐えられるかどうかをテストします。検査およびテストの間隔は、シリンダーの種類と使用目的によって異なります。

アルミニウム製のボンベは、炭酸飲料用の二酸化炭素などの食品グレードのガスを貯蔵するために使用できます。ただし、ボンベはこの用途のために特別に設計され、認証されている必要があり、ガスは食品グレードとして認証されている必要があります。

アルミニウム製のボンベは医療用酸素の保管に使用できますが、この用途向けに設計され、認定されている必要があります。また、ボンベは汚染を防ぐために使用前に洗浄および消毒する必要があります。

アルミニウムは一部の腐食性ガスと反応して、シリンダーが不安定になったり、爆発したりする可能性があるため、アルミニウム製のシリンダーは腐食性ガスの保管には推奨されません。代わりに、腐食性ガスの保管に適したシリンダーの材質に関する推奨事項については、製造元または資格のあるシリンダー検査員に相談してください。