The weight of aluminium bottle has been reduced further and further: the first beverage bottle 60 years ago weighed more than 80 grams. Today a 330 ml aluminium bottle only weighs about 13 grams.[br]

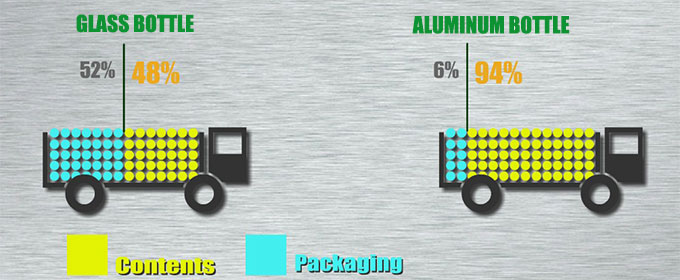

The lightness of aluminium packaging helps to save resources during filling, product transportation, storage and the transportation of scrap at the end of a product’s life.

Aluminium applications are effective at protecting perishable contents with the minimum amount of packaging material and therefore the maximum resource efficiency. Aluminium foil is by far the lightest ‘complete barrier’ material in a packaging composite. Virtually all cartons that require long term unrefrigerated protection are packed in laminates containing a layer of aluminium. A 6.5 micron foil layer renders the lightweight pack totally impervious to light, taint and gases.[br]

The nesting shapes of semi rigid foil containers are particularly suited to filling-machine magazines, while the stackability of stand up pouches, foil-lined cartons, cans and bottles make for excellent space and weight efficiency during storage, distribution and on the shelf.[br]

Beverage cans today are among the lightest beverage packages, while at the same time being extremely robust and protective of their contents. Today, cans can be produced with a wall thickness of 0.097 mm – as thin as a human hair.[br]

The can end is also becoming increasingly lighter: the new generation of can ends uses 10% less material than standard ends. A single gram of weight saved in the can, saves over 200,000 tonnes of aluminium globally per annum. Together with this weight benefit, the energy consumption as well as the CO2 emissions during transport are lowered – a further advantage for the environment.[br]