Custom aluminum bottles with different shapes & printings

Aluminium Bottle for Water

Aluminum Bottle for Promotion gift

Aluminum Bottle for Powder

Aluminum Bottle for Pet & Animal

Aluminum Bottle for Beauty & Personal Care

Aluminum Bottle For Beer

Aluminum Bottle for Beverage

Aluminum Bottle For Essential oil

Aluminum Bottle for E-cigarette & CBD

Aluminum Bottle for Nutrition

Aluminum Bottle for Home Care

Aluminum Bottle for Food oil

ALuminum Bottle for Liqueur

Aluminum Bottle for Agriculture & Fertilizer

Introduction

If you are looking for aluminum bottle packaging for your product, you must read this article. This article contains all the information related to aluminum bottles.

1. What are aluminum bottles?

1.1 Aluminum Introduction

Aluminum is a chemical element with the element symbol Al and the atomic number 13. It is the third most abundant element in the Earth’s shell, after oxygen and silicon, and the most abundant metal in the Earth’s crust. Aluminum is very light, with a relative density of 2.7g/cm³. It has good ductility, electrical conductivity, thermal conductivity, heat resistance, and radiation resistance and is widely used in important industrial fields such as aviation, construction, automobiles, electricity, and packaging.

In materials engineering, “aluminum” means all materials based on the element aluminum. This includes pure aluminum (at least 99% Al), ultra-pure aluminum (at least 99.7% Al).

1.2 What is an aluminum bottle?

Aluminum bottle is a bottle made of aluminum (or aluminium, in British English).

In some countries, it is also referred to as an aluminum flask or alu bottle.

Aluminum bottle is a type of metal bottle. It is made of a 1070A aluminum slug(99.7% Al). The production processes of aluminum bottles include impact extrusion, internal coating, Printing, necking, and thread forming steps.

Because of people being more environmentally conscious, the idea of using aluminum bottles will start to become more popular. However, you may notice that the price of aluminum bottles is a little bit higher than glass bottles or plastic bottles. So now the question arises of whether people will prefer buying the Aluminum bottles or not?

In 2021, a survey of 15,000 consumers showed that 57% were unlikely to buy products whose packaging was harmful to the environment. Furthermore, 44% refused to purchase products with harmful packaging. Results indicate that 73% of people would buy more environmentally friendly packaging. In addition, 20% say they are willing to pay more than 10% to purchase eco-friendly products.

Because of consumers have lost tolerance for packaging products that are not quickly or entirely recyclable, it demonstrates the replaceability of aluminum bottles, which are an excellent substitute for traditional plastic and glass bottles.

2. Why we use aluminum bottles?

Aluminum is a lightweight and durable metal – some bottles out there that are still being used after 30 years!There are seven reasons why you should consider using aluminum bottles over others.

2.1 Top 7 benefits of aluminum bottles?

Aluminum is a lightweight and durable metal – there are bottles out there that are still being used after 30 years! There are seven reasons why you should consider using aluminum bottles over others.

2.1.1 Decorative

Aluminum bottles can be printed in 360 degrees, and various printing processes offer designers a vast space for creativity. In a homogeneous packaging market, printed aluminum bottles make it easier to attract customers’ attention on the shelf and increase brand exposure.

2.1.2 Conductive

Aluminum has a higher heat transfer rate than iron, which is why it’s common to use aluminum bottles for drinks. As a result, aluminum bottles are very suitable as cold drink containers, such as beer and beverages.

2.1.3 Lightweight

Aluminum is one of the lightest metals available in the market. These bottles are easy to transport, store and recycle; therefore, consumers prefer them over other bottles. The portability of the aluminum bottle is also highly convenient for consumers to carry the product.

2.1.4 Formable

Aluminum is a soft and durable composition material that can be molded into any form or size as per your preferences, enhancing shelf differentiation, quickly responding to changing market trends, and making the development cycle shorter.

2.1.5 Protective

Aluminum bottles have a durable and seamless metal appearance that makes them an excellent choice for any liquid. In addition, they provide extra protection to your beverages and healthcare products from oxygen and moisture. These are two things dangerous enemies in the food and beverage industry because they can cause spoiling bacteria, mold growth, discoloration, and even slimy textures in your favorite drinks like beer or wine.

2.1.6 Recycle & Environmental

One of the critical differences between aluminum bottles and other materials is the ability to be recycled, and this property makes aluminum a better choice than its other counterparts. Recycle represents the environment. Using aluminum bottles means contributing to environmental protection. Let us Say Plastic Goodbye.

If your company wants to move towards to sustainable practices, using recycled aluminum bottles can be an excellent idea.

2.1.7 Anti-counterfeiting

Because of aluminum bottles are more difficult to produce than plastic and glass bottles, aluminum bottles can improve the appearance of the product and increase the difficulty of counterfeiting by others.

You can find more advantages in the following article.

2.2 Aluminum vs. Plastic vs. Stainless Steel vs. Tin vs. Glass

Next, we will compare aluminum bottles with other packaging one by one.

2.2.1 Aluminum Bottles vs. Plastic Bottles

When people mention plastics, they will think of white pollution. Plastics can also be recycled, but the process of recycling plastics is more complicated than aluminum. According to data from the Environmental Protection Agency, the average recycled content of aluminum is 68%, while the recycled content of plastics in the United States is only 10%.

- Aluminum bottles don’t contain bisphenol A (BPA), which is found in plastic bottles.

- The liquid inside the aluminum bottle benefits from the material since aluminum blocks 100% light from permeating the outside.

- Aluminum is more expensive than plastic, but the high price means people are more willing to recycle aluminum.

2.2.2 Aluminum Bottles vs. Stainless Steel Bottles

Stainless steel bottle was used 18/8 food-grade steel (AISI 304, SUS 304). An aluminum bottle is cheaper than stainless steel bottle based on the same capacity. Normally, stainless steel bottles are double-wall to form a vacuum, while aluminum bottles are single-wall and have wider applications. Due to welding, stainless steel bottles may leak. Aluminum bottles are formed in one piece, so it is 100% leak-proof.

The density of stainless steel is 7.8-8g/cm³, and aluminum is 2.7g/cm³. The wall thickness is similar, about 0.4mm. Therefore, the weight of the aluminum bottle is only 1/3 of the stainless steel based on the same capacity.

Aluminum is softer than stainless steel, so aluminum bottles have more shape changes than stainless steel bottles. Designers have more imagination space in appearance.

2.2.3 Aluminum Bottle vs. Tin cans

The tin can is welding process, 3-piece can. The shape is generally cylindrical and cannot be made into a bottle. Because it is heavy and easy to rust, it has been eliminated and replaced by an aluminum can. The only advantage is the low price.

2.2.4 Aluminum Bottle vs. Glass Bottles

The glass bottle is fragile and heavy (5 times than aluminum based on the same capacity). It means more transportation costs for manufacturers. And for consumers, it means inconvenience to carry.

Meanwhile, facilities for recycling glass are more difficult to obtain than aluminum bottles. Many local authorities refuse to collect or recycle glass together with other garbage. Because if different colors of glass are mixed during transportation, it is difficult to reuse. The energy of producing glass is 1/10 of virgin aluminum, but twice that of recycled aluminum.

3. What are aluminum bottles used for?

Today, many companies had begun to use aluminum bottles for their product packaging. Aluminum bottles had been used in various markets, such as food and beverage packaging, daily chemical products, and home care products.

Let’s introduce the application of aluminum bottles in different markets.

3.1 Sports bottle Market

Aluminum bottles were mainly used for sports bottles with a wide-mouth opening and screw cap. The capacity of the bottle is from 0.3L to 1.5L. The aluminum water bottle will be printed with images or monogrammed, such as Star Wars, Tinkerbell, Angry Birds, Disney Princess, and Mickey Mouse. Aluminum water bottles for sublimation printing are the perfect item for business promotions, personalized gifts, weddings, sports teams, and more.

The most popular aluminum sport bottle brands in the world are SIGG, Coleman, Laken, and Liberty.

3.2 Bottled Water Market

The market of global bottled water is expected to reach USD 307.6 billion by 2025. People are drinking more water than ever. People are interested in two growing offers: enhanced water that safely supports their health and recycles better packaging for the Earth. Aluminum water bottles offer the best of both worlds. The interest in alkaline water and sparkling water is exploding. Dasani is a representative brand. Aluminum bottles are water-resistant and rustproof. Consumers can use them for a long time before recycling.

3.3 Beer Market

We can find many aluminum bottles in the beer market. Top 20 beer brands in the United States, more than half brands are using aluminum packaging, mainly including:

- Bud Light: Bud Light Platinum, Bud light lime

- Corona Light

- Miller Lite

- Budweiser

- Heineken

- Coors Light

- Miller

- Busch Light

- Michelob Ultra

- Blue Moon

- Shock Top

- Mountain Dew

Top 10 aluminum beer bottle

In the 2018 FIFA World Cup, Budweiser launched a world cup aluminum collectible bottle. These promotional aluminum bottles create a collector’s item that would excite world football fans and beer drinkers alike.

3.4 Beverage Market

Coca-Cola aluminum bottle

Research shows that 55% of consumers are willing to pay 5% more at least for eco-friendly packaging and 20% of consumers are willing to pay 10%-20% more at least for eco-friendly beverage products.

Coca-Cola was the first company to use aluminum bottles. It mainly includes aluminum cola bottles, aluminum coke zero bottles, and aluminum sprite bottles. They are also the first company to use aluminum ROPP caps instead of crown caps in carbonated beverages. ROPP caps are more convenient than crown caps and can be reused, but the tightness is not as good as the latter. Then other beverage companies have gradually used aluminum bottles in their products, mainly including Pepsi, Red Bull, Starbucks, and Capri Sun.

3.5 Liquor Market

The Liquor market is very competitive. Some brands want to appeal to both environmentally conscious and quality-conscious consumers. Some brands wanted packaging that met requirements for durability and resealability. The answer proved to be aluminum bottles. DANZKA vodka, one of the leading premium vodka in the world, was the first company to use aluminum bottles in the liquor industry. Other brands include Stella rosa(wine), Sterling(wine), Chandon(wine).

Aluminum Bottle Liquor Market

3.6 Personal Care & Home Care Market

Research shows that 47% of consumers are willing to pay 5% more at least for eco-friendly packaging and 23% of consumers are willing to pay 10%-20% more at least for eco-friendly personal care products. Therefore aluminum bottles are also used in the personal care & home care industry. Their screw is compatible with the standards of plastic or glass bottles. The lid or pump head used on the plastic bottle can be directly used on the aluminum bottle. More importantly, if you use plastic bottles or glass bottles, you generally do not need to adjust the filling line, and there is no need for the labeling process.

In Europe, P&G Beauty provided Pantene, Aussie, Head & Shoulders, and Herbal Essences with a new aluminum reusable, refillable bottle system and a fully recyclable refill bag with less plastic than standard shampoo bottles 60%. The new filling system will be used by as many as 200 million households in Europe. It is estimated that starting from 2021, about 300 million virgin plastic bottles will cease each year.

3.7 Auto Care Market

In a highly competitive auto part market, as many professionals would know, although auto care products do work as advertised, the actual difference in the chemical compounds between a “budget” and “premium” product is small and often unnoticed by the majority. On the other hand, brand image and package make the most difference in the eye of average consumers.

aluminum bottle for care market

Suppose you put the same chemical content in a premium aluminum package. The consumer will more likely identify it as a premium product. In the eyes of your customers, if you are not cutting costs on packages, you are not cutting costs on the chemical content either. Furthermore, while your competitors are putting stickers on generic plastic bottles, you can better advertise your brand via aluminum printing techniques to highlight your product, making the package itself the best advertisement for your brand.

3.8 Industry and Agriculture Market

The aluminum bottle has low weight, high strength, lightweight, heat resistance, corrosion resistance, and chemical resistance. Therefore, aluminum bottles are commonly used in many industries and agriculture. Aluminum bottles are an ideal packaging to store and protect your chemical products. The fact that they block sunlight makes them ideal for many different packaging needs such as aluminum sample bottles, aluminum solvent bottles, aluminum pesticides bottles, aluminum fertilizers bottles, etc.

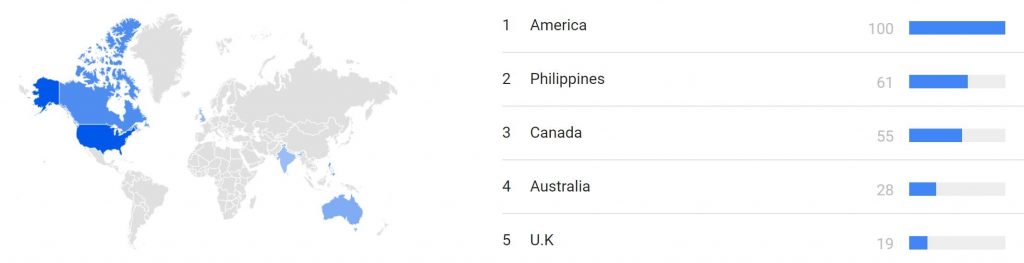

3.9 Which countries like to use aluminum bottles?

According to the Google Trends 2021 search index(English), the top 5 countries are aluminum bottles USA, aluminum bottles the Philippines, aluminum bottles Canada, aluminum bottles Australia, and aluminum bottles UK.

aluminum bottles in the world

These countries have solid environmental concepts, and most of them have the Plastic Limited Order. With the Plastic Limited Order launched in more and more countries worldwide, eco-friendly aluminum bottles must be the primary trend in the future market.

4. 6 Basic things about aluminum bottles?

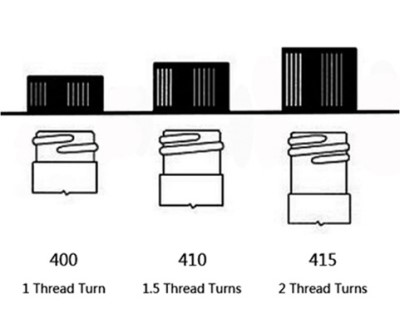

4.1 Screw thread

The aluminum neck finish was fixed and sealed by protruding threads. The bottle and its corresponding pump must have matching finishes. For example, a 24/410 bottle can only accept a 24/410 pump.

The aluminum neck finish was fixed and sealed by protruding threads. The bottle and its corresponding pump must have matching finishes. For example, a 24/410 bottle can only accept a 24/410 pump.

The first number refers to the diameter in millimeters measured outside the bottle thread. The second number refers to the thread style, “GPI”(Glass Packaging Association) or “SPI”(Plastics Industry Association ) finish. The aluminum bottle industry does’t necessarily follow the same standards, so it is best way to buy bottles and pump from the same supplier as much as possible.

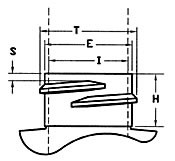

“H” Dimension: The height of the neck finish.

“S” Dimension: Measured from the top of the finish to the top edge of the first thread.

“I” Dimension: The inner diameter of the bottle neck.

“T” Dimension: The outside diameter of the thread.

“E” Dimension: The minor diameter measured across the root of the threads.

| MM | T | E | 400H | 410H | 415H | S | I | ||||||

| Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Min | |

| 20 | 19.89 | 19.48 | 17.75 | 17.35 | 9.08 | 9.04 | 14.45 | 13.69 | 19.23 | 18.46 | 1.32 | 0.56 | 10.26 |

| 24 | 23.87 | 23.47 | 21.74 | 21.34 | 10.54 | 9.78 | 16.79 | 16.03 | 24.69 | 23.93 | 1.55 | 0.79 | 13.1 |

| 28 | 27.64 | 27.12 | 25.25 | 24.74 | 10.47 | 9.78 | 18.36 | 17.06 | 27.86 | 27.1 | 1.55 | 0.79 | 15.6 |

| 33 | 32.14 | 31.52 | 29.74 | 29.14 | 10.62 | 9.86 | 33 | 32 | 1.55 | 0.79 | 20.1 | ||

| 38 | 37.5 | 36.88 | 35.1 | 34.5 | 10.62 | 9.86 | 1.55 | 0.79 | 17.45 | ||||

| 40 | 40.13 | 39.37 | 37.75 | 36 | 10.62 | 9.86 | 1.55 | 0.79 | 27.7 | ||||

| 43 | 42 | 41.25 | 39.62 | 38.86 | 10.62 | 9.86 | 1.55 | 0.79 | 29.6 | ||||

| 48 | 47.5 | 46.74 | 45.11 | 44.35 | 10.62 | 9.86 | 1.55 | 0.79 | 35.1 | ||||

| 51 | 50 | 49.1 | 47.6 | 46.71 | 10.75 | 10 | 1.55 | 0.79 | 37.6 | ||||

| 53 | 52.5 | 51.61 | 50.11 | 49.23 | 10.75 | 10 | 1.55 | 0.79 | 40.1 | ||||

| 58 | 56.5 | 55.6 | 54.1 | 53.22 | 10.75 | 10 | 1.55 | 0.79 | 44.1 | ||||

| 60 | 59.5 | 58.6 | 57.1 | 56.21 | 10.75 | 10 | 1.55 | 0.79 | 47 | ||||

| 63 | 62.51 | 61.62 | 60.12 | 59.23 | 10.75 | 10 | 1.55 | 0.79 | 50 | ||||

| 70 | 69.5 | 68.6 | 67 | 66.22 | 10.75 | 10 | 1.55 | 0.79 | 57 | ||||

| 75 | 74 | 73.1 | 71.6 | 70.71 | 10.75 | 10 | 1.55 | 0.79 | 61.5 | ||||

| 77 | 77.1 | 76.2 | 74.7 | 73.81 | 12.75 | 12 | 1.9 | 1.14 | 64.7 | ||||

| 83 | 83 | 82.12 | 80 | 79.07 | 12.75 | 12 | 1.9 | 1.14 | 70 | ||||

| 89 | 89.18 | 88.3 | 86.12 | 85.24 | 14 | 13.2 | 1.9 | 1.14 | 74.1 | ||||

| 100 | 100 | 99.1 | 96.95 | 96 | 15.55 | 14.8 | 1.9 | 1.14 | 85 | ||||

| 110 | 110 | 109.1 | 107 | 106 | 15.55 | 14.8 | 1.9 | 1.14 | 95 | ||||

| 120 | 120 | 119.1 | 117 | 116 | 17.8 | 17 | 1.9 | 1.14 | 105 | ||||

All dimensions in mm and converted from original SPI tables. The thread of the aluminum bottle will be little different due to process reasons.

4.2 ROPP Cap vs. Screw Cap

Roll-on-pilfer-proof(ROPP) caps and screw caps are often used in aluminum bottles. ROPP cap is formed by the capping head as the cap is applied to the bottle. The difference between ROPP cap and screw cap

Screw cap:

Sealed way: Manually

Pros

- Easy operation manually, no special capping machine needed;

- Flexible for small order quality.

Cons

- Simple close and open. No extra protection to avoid pilfer; Risky for loose;

- Sealed way: manually

Ropp cap:

Sealed way: Mechanically

Pros

- Pilfer proof. Must destroy cap before opening.

- Suitable for capping line for big quantity orders.

- The cap will fit the bottle 100% and more tightness.

Cons

- Need capping machine to work

- Need big quantity

4.3 Brimful capacity vs. Standard capacity

The brimful capacity (Full capacity) of a bottle is the maximum capacity of the packaging to hold liquid. It is also called overflow capacity.

Standard capacity (Filling capacity) is a normal volume for commercial use, and it is normally up to the shoulder level of a bottle.

For aluminum bottles, usually, go with a 5%-7% of gap. Companies are considering 10% of the gap for pump bottles because the pump will occupy space, especially foam pumps.

How to measure Brimful capacity?

1. Estimation method: V=π*r2*H

V represents volume, π=3.14,

D: The bottom diameter of the bottle

H: The height of the bottle, usually to the shoulder

2. Software simulation: use 3D software to simulate the capacity according to the product drawings

3. Weighing method: put the bottle on the electronic scale to reset to zero, fill the bottle with water, and the weight is the volume

Comparative advantages and disadvantages of the three methods

| Method | Pro | Cons |

| Estimation | Fastest | The data is not accurate, especially for special-shaped bottles |

| Software | The data is more accurate. No samples are needed | The speed is slow, and the drawing of the product is required |

| Weighing | The fastest and most accurate | Sample needed |

4.4 Plastic Scew vs. Aluminum Screw

We use plastic screws on some aluminum bottles to replace aluminum threads, mainly because of the following :

Pros

- More standard, small tolerance, high precision

- Abrasion-resistant

- Special threads that are not available in aluminum threads to fit custom pump head or cap

Cons

- Low production efficiency, high cost

- Inconvenient recycling

4.5 CRC ( Child Resistant Cap)

A child-resistant Cap or CRC Cap is a “special packaging cap” specifically for children below five years. The CRC cap aims to reduce the risk of poisoning in children via the ingestion of hazardous items. CRC caps in aluminum bottles are mainly used in Pharmaceuticals, CBD, Chemicals, etc.

4.6 Is it safe to use aluminum bottles?

The aluminum bottle is safe for drinking. We know that there have been some concerns surrounding the safety of aluminum related to the food industry. We would never produce aluminum bottles that are harmful to our customers. We are using inner coating from PPG and Valspar, and both of them guarantee BPA-free components.

We always go further when it comes to safety tests. We carry out the certified tests imposed by safety regulations and independent tests from third-party laboratories every year that help us exceed stipulated safety levels. We have food-grade test reports from the US FDA and European LFGB that prove our aluminum drinking bottles’ safety.

Our bottles have been tested with many different drinks, including acidic beverages, sparkling beverages, milk, alcohol, and apple and lemon juice. However, we recommend not leaving drinks with natural fermentation processes inside the bottle for long periods, such as apple juice or milk. This natural process can produce gases and strong smells, which can be difficult to eliminate.

Our company has decades of aluminum bottle production experience, and we are backed by thousands of customers’ positive reviews about our products.

5. Surface treatment & Printing

The appearance of packaging usually determines what ends up in the shopping cart, making it all the more important to have attractive Printing on the packaging. In order to cope with any shape, any material, we offer you various printing technologies.

5.1 Polish

We use a high-speed rotating polishing wheel to press against the aluminum bottle so that the abrasive can roll and micro-cut the surface of the aluminum bottle, to get a bright processing surface.

5.2 Paint

We use spray guns to spray different colors of paint on the surface of aluminum bottles. Generally, customers provide us with a PANTONE color. Paint colors for aluminum bottles are: pink, red, black, white, and silver.

5.3 Anodized

Anodizing is a process in which an aluminum bottle is used as an anode, placed in an electrolyte solution for energization, and an aluminum oxide film is formed on the surface by electrolysis.

5.4 UV Coating

The atoms of the material in the vacuum chamber are separated from the heating source and hit the surface of the aluminum bottle, making the surface appear bright silver, bright gold, etc.

5.5 UV printing

UV printing is a unique digital printing method utilizing ultraviolet (UV) light to dry or cure the ink, adhesives, or coatings almost as soon as it’s hit the aluminum. UV printing does not need to make a printing plate. But UV printing takes a long time (10-30 minutes for a bottle), so it is generally used for samples. And it can only be printed on the flat part of the bottle, not on the bottle’s shoulder.

5.6 Screen printing

Screen printing is uses for screen and ink to transfer into an image onto a bottle. Each color may be used for each screen. If a design with multiple colors, it will need multiple screens. There are strong arguments in favor of screen printing for the decoration of bottles: Because of the high color opacity, the product does not shine through, even on a black bottle. Screen printing colors remain unchanged even under strong light.

5.7 Heat transfer printing

Heat transfer printing is a method of decoration method by heating and pressure. First, your custom logo or design is printed onto transfer film. Then the ink is thermally transferred from the film to tubes by heat and pressure.

5.8 offset printing

Offset printing is a printing method in which the graphics on the printing plate are transferred to the substrate through the rubber. Rubber plays an irreplaceable role in Printing, such as it can make up for the uneven surface of the substrate so that the ink can be fully transferred

5.9 Printing difference

The main printing processes for custom printed aluminum bottles are silk screen, heat transfer printing, and offset printing. The following are the differences between these three printings:

| Printing | color | Gradient | Shoulder printing | MOQ |

| silk screen | <2 color | no | NO | 5000 |

| heat transfer printing | 9 color | yes | NO | 5000 |

| offset printing | 9 color | yes | YES | 50000 |

5.10 4 Basic things about aluminum bottles printing

5.10.1 PANTONE Color

PANTONE color is a world-renowned color authority. It covers the color communication system of Printing, textile, plastics, graphics, digital technology and other fields. It has become the international unified standard language for the exchange of color information today. We recommend that customers mark the Pantone color number on the artwork. Tools like Adobe Illustrator & Photoshop can substitute a hex or RGB value for the closest Pantone color.

There are there types of PANTONE color in aluminum bottle artwork.

- Coated color card: end with C letter, such as 3330C

- Uncoated color card: end with U letter, such as 3330U

- Metal color card: start with 8, such as 8312

5.10.2 9 colors printing

Nine colors printing means that there are only nine spot colors (PANTONE color) on the design draft at most. If your artwork exceeds nine colors, a few colors can be mixed by color contrast. The printing effect of mixed color is worse than spot color.

5.10.3 Create Outlines

The Create Outline function allows you to convert your text into objects. Because our computer may not have the font of the customer’s artwork, the designer will prompt that the font is missing when opening the artwork. Therefore, the designer will create outlines before sending artwork. The artwork can be opened regardless of whether there are fonts on our computer.

5.10.4 Requirements For Artwork

Following requirements are preferred:

- Two files ( ai and pdf), ai is used for modify and plate making, pdf is used to confirm the overall effect

- Sofware: Illustrator CC 2018 (or lower), CorelDRAW X8(or lower)

- Vectorized Illustrator file (ai, eps)

- Fonts to be delivered separately (only used in case of text changes)

- Illustrations in artwork: 300dpi should be included

Additional requirements:

- Colors: The number of plates/colors is limited to 8. Fine screens, barcodes, small positive texts can / must be placed on a separate plate

- Full-color work: Printing of more than two colors on top of each other is limited because of ink contamination. Special Pantone colors have preference over CMYK.

- Barcode Bars: Should be in a horizontal position

- Colors: Basecoat: white, transparent; Inks: all PANTONE Colours; Over-varnish: gloss, matt

- Type size: Positive text ≥ 5pt;Negative text ≥ 6pt

- Line size: Positive lines ≥ 0.4p; Negative lines ≥ 0.5pt

6. Aluminum Bottle Production Process

We have two types of aluminum bottles production; one is fully automatic production, the other is semi-automatic production. The difference between them is below.

| Semi-automatic | Fully automatic | |

| Production capacity | 10,000 PCS/day every production line | 100,000 PCS/day every production line |

| Printing | Heat transfer printing Screen Printing | Offset Printing |

| MOQ | 5000 PCS | 50000 pcs |

| Mold fee | 1,000 to 10,000 USD | 20,000 to 100,000 USD |

Now we introduce the production process of the automatic line.

6.1 Impact Extrusion Presses

Impact extrusion presses play an important role in production lines for aluminum bottles. It’s the first machine in a long and complex manufacturing process. The starting material is aluminum slugs several millimeters thick. During reverse impact extrusion, the aluminum slug flows between the die and the punch against the press movement during the forming process. This is how thin-walled aluminum tubes are created.

6.2 Trimming and Brushing

The aluminum tube must be the same length. An essential step in the elaborate decoration is trimming to a given coat length. When aluminum tubes leave the impact extrusion presses, they do not meet the requirements for painting and Printing. Burr-free cutting first brings them to the desired size, the trimmed length. The aluminum is still rough and streaky, but additional brushing of the can remove the tiny unevenness and create a smooth surface – the ideal preparation for base coating.

6.3 Transfer

In order for production to run fully automatically, the tubes have to be transferred from one transport chain to the next. The tubes are first removed from the chain bars onto a rotating drum with vacuum troughs. If the vacuum is briefly interrupted, the tube falls onto a second drum, which is located below the first. From there, the part is pushed back onto the transport rods of the subsequent chain – the transfer is complete.

6.4 Washing

The surfaces of aluminum tubes must be degreased, cleaned, and dried before decoration. Another washing process is required later if these containers are used in the food industry. Cleanliness is the top priority to make sure that the coating layer protects the tube surface perfectly. Washing systems clean aluminum tubes inside and out with a washing solution so that the coating adheres optimally.

6.5 Drying

The quality of tube decoration will only be good if Printing, coating, and drying make a perfect match.

6.6 Iner Coating

Take out dry bottles and put them into the inner coating machine. There are nine guns to make sure everywhere has an inner coating. Then put them in the backing box again, and the temperature reached 230 degrees. We use different inner coating types according to product usage. Food products use food-grade coating (BPA Free or BPA-Ni). Use an anti-corrosive inner coating for strong acid and strong alkali.

6.7 Base Coting

The base coating creates the basis for clean Printing on aluminum tubes. There are two base coatings, white and transparent. The white base coating fulfills two tasks in decorating: It evens out the fine unevenness on the surface of aluminum tubes and forms the background for the print image. A transparent base coat supports the attractive character of brushed aluminum – an elegant solution that makes a perfect impression on tubes.

6.8 Offset Printing

Offset printing, also called offset lithography, is an indirect flat printing process. In the first step, the ink is transferred from the printing block onto a rubber cylinder, in a second step, onto the tubes. The offset printing machine supports up to 9 colors, and these 9 colors are printed on the tube almost at the same time.

6.9 Top Coating

Top coating is another layer of lacquer that refines the surface and protects the print from damage. Even the most attractive printed image quickly loses its advertising effect if it suffers from abrasion or scratches. The always transparent top coating protects the surface of the container from mechanical damage after Printing. There are two choices in the top coating, mat or glossy. It should be noted here that although the effect of matte is better, it is easier to stain than glossy.

6.10 Necking

Narrow waist, attractive shoulders – This is the key process for bottle shaping. This shaping process, known as necking, is technically demanding because the bottles are already printed and coated. But the sophisticated necking process is worth it! Because consumers always like bottles with unique shapes. The tube gets shaped into a bottle with the help of 20-30 differently necking molds, each one moving the tube further towards the final shape. The aluminum tube will change a little in each process. If the deformation is too large, the tube will break or have a deformation step. If the deformation is too small, the number of molds may be insufficient.

Necking is A challenging task because the tubes have already been printed and coated. The coated must be elastic enough to withstand the deformation. And the necking molds are always spick and span to protect the base coating and the Printing.

If the shoulder shape is about an attractive appearance, the technical process of the bottle opening is more important, depending on the closure: spray head, valve, hand pump, or screw cap with thread. The shape of the opening must be adapted to this in any case. Therefore, the last few necking molds are crucial.

7. What aluminum bottle do we offer?

Aluminum Bottle Size

The capacity of our aluminum bottles typically ranges from 10ml up to 30L, depending on your needs. The small aluminum bottle is used for essential oil, and the large aluminum bottle is used for the chemical sample.

The common capacities (fl. oz) in aluminum bottles are: 1oz, 2oz, 4oz, 8oz, 12oz, 16oz, 20oz, 24oz, 25oz, 32oz.

The common capacities (ml) in aluminum bottles are: 30ml, 100ml, 187ml, 250ml, 500ml, 750ml, 1 lite, 2 liter.to

Aluminum Beer Bottles

- Cap: crown cap

- Opening: 26.6mm with crimping

- Capacity: 250ml, 330ml, 355ml, 473ml

- Diameter: 53mm,59mm

- Height: 170-200mm

- MOQ: 30,000 PCS

Aluminum Beverage Bottles

- Cap: aluminum ropp cap

- Opening: 38mm with crimping

- Capacity: 200ml, 300ml, 500ml, 660ml

- Diameter: 53mm,66mm

- Height: 150-240mm

- MOQ: 30,000 PCS

Coke Aluminum Bottle

- Cap: aluminum ropp cap

- Opening: 28mm with crimping

- Capacity: 250ml, 8.5 oz

- Diameter: 53mm

- Height: 175mm

- MOQ: 30,000 PCS

Aluminum Wine Bottle

- Cap: aluminum ropp cap

- Opening: 30mm with PP neck

- Capacity: 350ml, 500ml

- Diameter: 59mm

- Height: 175-240mm

- MOQ: 30,000 PCS

Aluminium Drink Bottle

- Cap: aluminum ropp cap

- Opening: 28mm

- Capacity: 50ml, 60ml, 2oz

- Diameter: 35mm

- Height: 95-150mm

- MOQ: 30,000 PCS

Aluminum Liquor Bottles

- Cap: PP ropp cap

- Opening: 30mm, 35mm

- Capacity: 500ml, 750ml, 1000ml

- Diameter: 66mm, 73mm, 80mm

- Height: 110-260mm

- MOQ: 30,000 PCS

Aluminum can water bottles

- Cap: aluminum ropp cap

- Opening: 38mm

- Capacity: 250ml, 280ml, 330ml, 440ml

- Diameter: 66mm

- Height: 123-168mm

- MOQ: 100,000 PCS

Aluminum oil bottles

- Cap: oil cock

- Opening: 28.5mm

- Capacity: 250ml, 500ml

- Diameter: 50mm, 59mm

- Height: 190mm,240mm

- MOQ: 10,000 PCS

Aluminum pill bottle

- Cap: oil cock

- Opening: 28.5mm

- Capacity: 60 pill

- Diameter: 53mm

- Height: 105mm

- MOQ: 30,000 PCS

Aluminum cosmetic bottles

- Cap: Aluminum screw caps, PP cap

- Opening: 24/410, 28/410 Screw top

- Capacity: 30-1500ml

- Diameter: 22-88mm

- Height: 55-295mm

- MOQ: 10,000 PCS

Aluminum spray bottles with pump

- Cap: Aluminum screw caps, PP cap

- Opening: 20/410, 24/410 fine mist spray

- Capacity: 30-250ml

- Diameter: 22-50mm

- Height: 55-295mm

- MOQ: 10,000 PCS

Aluminum lotion bottles

- Cap: Lotion Pump

- Opening: 20/410, 24/410

- Capacity: 30-1500ml

- Diameter: 22-88mm

- Height: 55-295mm

- MOQ: 10,000 PCS

Aluminum perfume bottle

- Cap: aluminum spray pump

- Opening: 20/410, 18/410

- Capacity: 50-200ml

- Diameter: 22-88mm

- Height: 100mm

- MOQ: 10,000 PCS

Aluminum dropper bottle

- Cap: Dropper

- Opening: 20/410

- Capacity: 30ml, 50ml, 60ml

- Diameter: 36-45mm

- Height: 75-150mm

- MOQ: 10,000 PCS

Aluminum foam bottle

- Cap: Foam Pump

- Opening: 40mm,43mm

- Capacity: 250ml, 300ml, 350ml

- Diameter: 66mm, 73mm, 80mm

- Height: 120-160mm

- MOQ: 10,000 PCS

Aluminum Trigger Pump bottle

- Pump: trigger spray

- Opening: 24/410, 28/410

- Capacity: 100-1500 ml

- Diameter: 45-88 mm

- Height: 55-295 mm

- MOQ: 10,000 PCS

Aluminum powder shaker bottle

- Cap: aluminum powder cap

- Opening: 26mm, 40mm

- Capacity: 120-1250ml

- Diameter: 59mm, 66mm, 73mm

- Height: 100-160mm

- MOQ: 10,000 PCS

Aluminum bottles for essential oils

- Cap: crown cap

- Opening: 26.6mm with crimping

- Capacity: 250ml, 330ml, 355ml, 473ml

- Diameter: 53mm,59mm

- Height: 170-200mm

- MOQ: 30,000 PCS

Aluminum chemical bottles

- Cap: Cap: PP cap, PE plug

- Opening: 62mm

- Capacity: 2-30Litre

- Diameter: 95-300mm

- Height: 300-450mm

- MOQ: 1,000 PCS

Aluminum fuel treatment bottle

- Cap: Aluminum ropp cap

- Opening: 24mm

- Capacity: 50-600ml

- Diameter: 35-73mm

- Height: 70-235mm

- MOQ: 10,000 PCS

8 How to customize in aluminum bottle manufactory?

After the above introduction, if you decide to use blank aluminum bottles, we will guide you on choosing an aluminum bottle that is suitable for your products.

In the first step, you will have to describe the product’s usage, capacity, and quantity. The purpose is mainly related to the inner coating and outer coating of your bottles. We will use this information and our understanding of your needs to choose an appropriate inner or outer coating for your product content. For example, an inner coating will be used for most food and beverage products, and a corrosion-resistant internal coating will be used for cleaning products. On the other hand, the external coating mainly has requirements for some products that require high-temperature sterilization.

We will select the existing mold to recommend your suitable bottle type depending on the way to use and the capacity. Based on your packaging needs, the bottle can be select dropper, pump, fine mist sprayer, screw cap, or Ropp, etc. However, the quantity is associated with the production line we will using to manufacture your products. We will always be here to assist you, finding a suitable production plan to boost the market value of your products; the size of the business does not matter. After the above discussion, we now have the appearance of the product.

In the next step, we will provide you with the printing size depending on the type of bottle you have chosen. Either your designer can design your brand pattern, or we can also make some basic patterns for you. We will create a 3D rendering for you, by using the design draft to see the beginning effect of the product. Also, we can use digital printer for some simple design drafts,therefor to directly print the design drafts on the bottle in just 24 hours, and it will enable you to see the natural effect and describe it to you.

Lastly, we will create some samples after confirming design drafts, and the samples will be sent to you for filling and compatibility testing. Then, we can proceed further to mass production after all the tests have been passed.

The procedures are described above fundamental processes; depending on your products, we will assist you in listing some of the problems that require attention in using aluminum bottles. You do not have to search if you are looking for custom aluminum bottles. You can find a one-stop solution for aluminum bottles at SHINING aluminum packaging.

Please feel free to contact us through email if you have any queries about the customer aluminum bottles. We have experts that are always ready to assist you and will contact you back within 24 hours to tell you about the possibility of customizing your aluminum bottle price.

SHINING aluminum packaging is the most professional aluminum bottle manufacturer, aluminum bottle supplier, aluminum bottle wholesale in china.